Application Scenarios:

In a large combined-cycle power plant, operators in the central control room need real-time data from the gas turbine governor—speed, temperature, valve positions, alarms—displayed on their main DCS screens for monitoring and remote start/stop commands. The WOODWARD 5464-414 DCS module installed within the turbine’s NetCon™ controller makes this possible. It acts as a secure gateway, translating the turbine’s internal control data into a standard industrial protocol (like Modbus TCP/IP or serial-based protocols) and transmitting it over Ethernet or serial links to the plant’s DCS. Without a functioning 5464-414 DCS card, the turbine becomes a “island of automation,” forcing operators to rely solely on the local panel, reducing operational efficiency and compromising plant-wide control integration. Its role is critical for visibility, data logging, and coordinated control of the prime mover within the broader process.

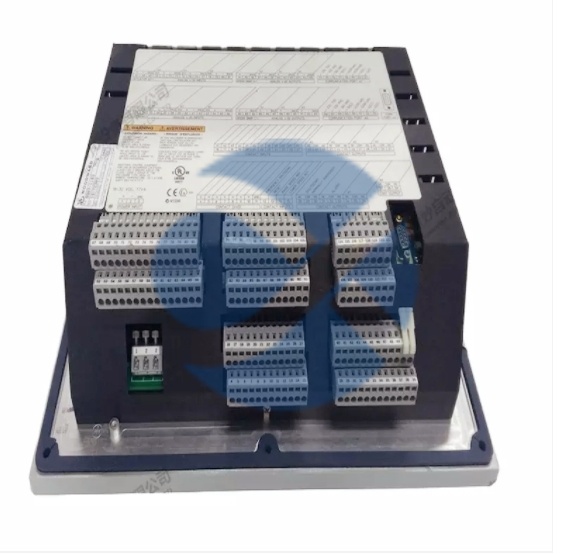

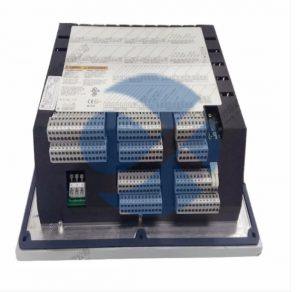

Parameter:

Technical Principles and Innovative Values:

The WOODWARD 5464-414 DCS module is engineered to provide robust connectivity while maintaining the integrity and security of the critical control network.

Innovation Point 1: Dual-Port, Multi-Protocol Gateway Architecture: The module’s design incorporates both a high-speed Ethernet port and a configurable serial port. This provides exceptional integration flexibility. The Ethernet port can handle high-data-throughput Modbus TCP connections to modern DCSs, while the serial port can maintain a legacy Modbus RTU link to a separate PLC or serve as a dedicated service port. This dual-homing capability supports redundant communication paths or multi-destination data publishing, enhancing system availability.

Innovation Point 2: Secure Network Segregation and Data Mapping: The 5464-414 DCS is not a simple pass-through. It operates as a defined gateway, carefully mapping specific, pre-configured data points (registers) from the NetCon™ controller’s memory to the external network. This “publish-subscribe” model, managed via Woodward’s toolset, creates a functional firewall. It prevents unauthorized access or malicious traffic from the plant network from reaching the sensitive real-time control loop, a crucial security feature for critical infrastructure.

Innovation Point 3: Deterministic Performance within Control Chassis: Unlike an external protocol converter, the 5464-414 DCS is a card integrated directly into the NetCon™ backplane. This provides deterministic, high-speed access to the controller’s internal data table with minimal latency. External devices poll the 5464-414 DCS for data, and it responds with the latest cached values without interrupting the primary control task’s execution, ensuring control performance is never compromised for communications.

Application Cases and Industry Value:

Case 1: Petrochemical Plant Turbine-Generator Upgradation: A refinery upgraded its central DCS and needed to integrate an older turbine-generator unit controlled by a Woodward NetCon 5000. The existing proprietary communication was incompatible. Engineers installed and configured a WOODWARD 5464-414 DCS card into the NetCon chassis. Using Modbus TCP, they mapped over 200 critical tags (speed, megawatts, temperatures, valve commands) to the new DCS. This provided operators with full visibility and remote start/stop capability from the modern control room. The project lead noted the 5464-414 DCS was the “linchpin” of the integration, avoiding a $100k+ controller replacement and extending the asset’s service life with modern connectivity.

Case 2: Remote Pipeline Compressor Station Monitoring: For a remotely located gas compressor station, the operational data from its engine-driven compressors needed to be transmitted to a central SCADA system hundreds of miles away via a serial radio link. The WOODWARD 5464-414 DCS module in each NetCon controller was configured for Modbus RTU on the serial port. It reliably packaged the compressor’s vital signs (discharge pressure, engine RPM, health status) into a serial stream for the radio modem. This enabled 24/7 remote monitoring, predictive maintenance alerts, and reduced the need for physical site visits, significantly lowering operational costs and improving response times to developing issues.

Related Product Combination Solutions:

NetCon™ 3000 / 5000 Controller: The main control chassis where the 5464-414 DCS module is installed.

ProTech™ Overspeed Protection System: A critical safety system; its trip status and diagnostics are often communicated to the DCS via the NetCon controller and the 5464-414 DCS gateway.

Woodward ToolKit Software: The essential configuration suite used to set up the data mapping, protocol settings, and IP configuration for the 5464-414 DCS card.

Plant DCS/SCADA System (e.g., Emerson DeltaV, Siemens PCS 7): The ultimate destination system that receives data from and sends commands via the 5464-414 DCS.

Network Switch (Managed): Connects the Ethernet port of the 5464-414 DCS to the plant network; a managed switch allows for VLAN segmentation for added security.

Industrial Protocol Gateway (e.g., ProSoft, Red Lion): In complex multi-vendor networks, these may sit between the 5464-414 DCS and the final DCS to translate between Modbus and other protocols like OPC UA or EtherNet/IP.

HMI (Human-Machine Interface): A local or remote HMI can connect directly to the 5464-414 DCS (often via Ethernet) to provide a dedicated operator graphical interface for the turbine/engine.

Installation, Maintenance, and Full-Cycle Support:

Installation of the WOODWARD 5464-414 DCS module requires the NetCon controller to be powered down. The technician simply unlocks and opens the controller chassis, identifies an available slot compatible with communication modules, and firmly seats the card into the backplane connector, securing it with the retaining screw. The physical network cables (Ethernet CAT5e/6 and/or serial cable) are then connected to the card’s front-face ports and routed to the external network infrastructure.

Maintenance is primarily preventive and network-focused. Ensure the controller cabinet environment is clean and cool. The most common “maintenance” task involves configuration management: using Woodward ToolKit to back up the 5464-414 DCS module’s configuration (IP addresses, data maps) after any changes. The module itself is solid-state with no user-serviceable parts. If diagnostics indicate a failure, replacement with a genuine WOODWARD 5464-414 DCS card is required, followed by a restoration of the configuration backup. We provide the authentic OEM module and can offer guidance on configuration recovery to ensure a smooth reintegration into your control architecture, minimizing re-engineering effort.

Contact us for the genuine WOODWARD 5464-414 DCS module and expert support to seamlessly integrate your turbine control into your plant network