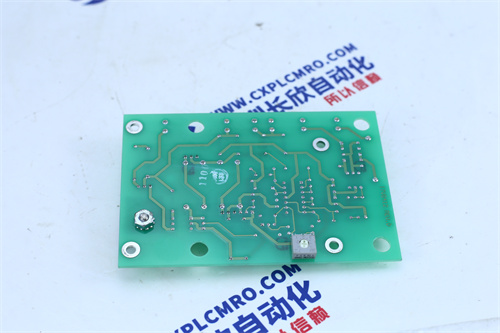

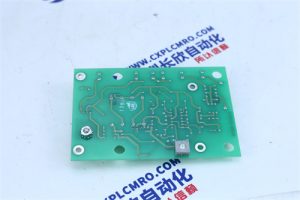

CP800

Product Name

ABB CP800 Communication Processor Module for Symphony Plus DCS(The naming follows ABB’s Symphony Plus system conventions:

- “CP800”: Identifies the “Communication Processor (CP)” series, with “800” aligning with the HPC 800 controller family for unified system compatibility.

- “Communication Processor Module”: Highlights its core role—facilitating data transmission between the HPC 800 controller, I/O subsystems (e.g., S800 I/O), and the Ethernet-based Plant Network (PN 800) 。

This module acts as a “system data gateway,” ensuring real-time, reliable communication across distributed control components in industrial processes.)

2. Product Description

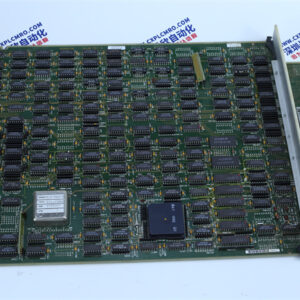

The CP800 is an industrial-grade communication processor engineered by ABB to address core challenges in DCS data exchange: fragmented subsystem communication, slow control response, and limited scalability. As a key component of the Symphony Plus DCS, it integrates high-speed data routing, multi-subsystem compatibility, and redundant communication capabilities—making it indispensable for:

- Oil & Gas Industry: Coordinating pipeline pressure sensors (S800 I/O) and HPC 800 controllers, where delayed data transmission could cause safety incidents.

- Chemical Processing: Enabling real-time sync between reactor control loops and plant-wide SCADA systems, ensuring compliance with process safety standards.

- Power Generation: Linking turbine monitoring devices to centralized control rooms, supporting grid stability through rapid data feedback.

- Manufacturing: Integrating machinery control systems (e.g., Harmony rack I/O) into unified automation networks, optimizing production line efficiency 。

Key Functional Advantages

-

High-Speed Multi-Subsystem IntegrationSupports simultaneous communication with SD series I/O, Harmony rack I/O, and S800 I/O subsystems , enabling closed-loop control of over 5,000 I/O points in less than 250 ms. Its 256 MHz 32-bit Freescale ColdFire processor and 64 MB DRAM ensure low-latency data routing, critical for time-sensitive processes like batch chemical production 。