958481321210 PD212

Product Name

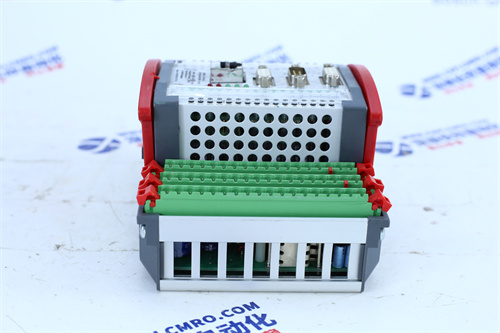

Honeywell Experion PKS Series 16-Channel Mixed Digital Input/Output (I/O) Module (Model: PD212; Part Number: 958481321210)

(Model & Part Number Interpretation:

- PD212 (Model):

- PD: Core product line prefix for Honeywell’s Experion PKS “Process I/O” modules, denoting compatibility with Experion C300/C200 controllers and membership in the “PD” family of modular I/O solutions for process automation.

- 212: Hardware configuration code; “2” specifies mixed I/O functionality (8 digital inputs + 8 digital outputs), “12” indicates 24 V DC signal levels (industrial standard for discrete sensors/actuators) and enhanced diagnostic capabilities (channel-level fault detection).

- 958481321210 (Part Number):

- 958481: Honeywell’s regional part code for Experion PKS I/O modules, confirming compliance with global process safety standards (IEC 61508, ISA 84).

- 321210: Revision and compliance suffix; “32” denotes firmware revision 3.2 (optimized for low-latency communication and safety loop integration), “1210” verifies ATEX/IECEx hazardous area certification and compatibility with Honeywell’s Safety Manager.

- Core Positioning: The “mixed I/O hub for Experion PKS DCS,” enabling flexible discrete signal monitoring and actuation to support process interlocks, emergency shutdown systems (ESD), and routine equipment control—essential for maintaining operational safety and efficiency in process industries. )

2. Product Description

The 958481321210 PD212 is a dedicated 16-channel mixed digital I/O module developed by Honeywell for the Experion PKS Distributed Control System, a flagship platform in oil & gas, chemical, and refining process automation. It integrates 8-channel digital input / 8-channel digital output functionality, safety-compliant design, channel-level fault protection, and real-time diagnostics to address three key challenges of process I/O systems:

- Flexible Process Control: Combines 8 digital inputs (for monitoring sensors like limit switches, pressure switches) and 8 digital outputs (for controlling actuators like solenoid valves, alarm relays) in a single module—reducing control cabinet space by 40% compared to separate input/output modules. This flexibility is critical for compact process skids (e.g., chemical dosing units) where space is limited.

- Safety-Compliant Operation: Complies with IEC 61508 SIL 2 (for safety-related I/O loops) and ISA 84.00.01 (process safety standards), featuring channel-level galvanic isolation (500 V DC) and redundant signal paths for critical inputs/outputs. This ensures reliable operation in ESD systems—e.g., triggering a valve shutdown within 10 ms if a pressure switch detects an overpressure condition.