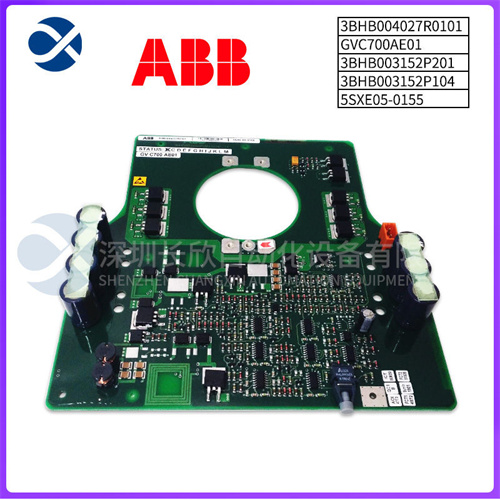

3BHB004791R0101

Product Description

The 3BHB004791R0101 is a high – performance industrial module engineered to meet the demanding requirements of modern automation and control systems. It serves as a critical component for facilitating seamless communication, precise data processing, and reliable control in various industrial applications.

In manufacturing plants, this module acts as a central hub for coordinating the operation of production lines. It can interface with a multitude of sensors, such as temperature, pressure, and position sensors, collecting real – time data on the status of machinery. By analyzing this information, the 3BHB004791R0101 sends out accurate control signals to actuators, ensuring smooth and efficient production. For example, in an automotive assembly line, it can synchronize the movements of robotic arms, conveyor belts, and painting systems, optimizing productivity while maintaining high – quality standards.

In power generation facilities, the module plays a vital role in monitoring and regulating power – related processes. It connects to generators, transformers, and circuit breakers, gathering data on electrical parameters like voltage, current, and power factor. Based on this data, it can make real – time adjustments to power – generation equipment, ensuring stable power output and grid reliability.

The 3BHB004791R0101 features a rugged and durable design, built to withstand harsh industrial environments. It is resistant to electrical interference, mechanical shocks, and extreme temperatures, ensuring consistent performance even in the most challenging conditions. Its modular architecture allows for easy installation, maintenance, and expansion, reducing system downtime and enhancing the overall flexibility of industrial control systems.

Product Parameters

- Electrical Parameters

- Input Voltage: Operates on a wide – range input voltage of 100 – 240V AC, 50/60Hz, providing compatibility with diverse industrial power sources globally. This broad voltage tolerance ensures stable operation even in regions with fluctuating power supplies.

- Power Consumption: Designed to be energy – efficient, with a typical power consumption of around 15 – 25W under normal operating conditions, minimizing energy costs and heat generation within control cabinets.

- Communication Parameters

- Communication Protocols: Supports multiple industrial – standard communication protocols, including Ethernet/IP, Profibus DP, Modbus TCP/RTU, and CANopen. This multi – protocol support enables seamless integration with a wide variety of industrial devices, such as programmable logic controllers (PLCs), human – machine interfaces (HMIs), and other intelligent sensors and actuators.

- Data Transfer Rate: When using Ethernet/IP, it can achieve a high data transfer rate of up to 100Mbps, ensuring rapid and reliable data exchange between the module and other networked devices. For serial – based protocols like Modbus RTU, the data transfer rate can reach up to 115.2 kbps.

- I/O Parameters

- Digital Input Channels: Equipped with 16 isolated digital input channels, capable of detecting binary – state signals from external devices such as switches, relays, and proximity sensors. The input channels can accept a voltage range of 5 – 30V DC for logic – level detection.

- Digital Output Channels: Features 12 isolated digital output channels, each capable of driving loads up to 2A at 24V DC. These outputs can be used to control relays, solenoid valves, and other discrete – control devices.

- Analog Input Channels: Has 8 analog input channels, which can accept various analog signals, including 4 – 20mA, 0 – 10V, and thermocouple signals. The analog inputs offer high – precision resolution, typically 16 – bit, for accurate data acquisition.

- Analog Output Channels: Includes 4 analog output channels, providing analog signals in the range of 4 – 20mA or 0 – 10V with an accuracy of ±0.1% of the full – scale range, enabling precise control of analog – based actuators.

- Environmental Parameters

- Operating Temperature Range: Can function reliably within a temperature range of – 40°C to + 85°C, making it suitable for use in diverse industrial environments, from cold storage facilities to high – temperature manufacturing plants.

- Relative Humidity: Withstands a relative humidity of 5% – 95% non – condensing, ensuring stable performance in humid industrial settings, such as near water treatment plants or in coastal regions.

Product Specifications

- Physical Specifications

- Dimensions: Compact in size, with approximate dimensions of 200mm (length) × 120mm (width) × 60mm (height), facilitating installation in standard industrial control cabinets and saving valuable space.

- Weight: Weighs around 1.8 kg, which is manageable for installation and maintenance by technicians.

- Mounting Method: Supports DIN – rail mounting or panel – mounting, providing flexible installation options to adapt to different industrial control setups.

- Functional Specifications

- Signal Conditioning: Incorporates advanced signal – conditioning circuitry for both analog and digital signals. This circuitry filters out noise, linearizes analog signals, and performs necessary conversions to ensure accurate data representation for the control system.

- LED Indicators: Equipped with LED indicators on the front panel for power status, communication activity, and I/O channel status. These visual indicators allow operators to quickly monitor the module’s operation and identify any potential issues.

- Diagnostic Functions: Features comprehensive built – in diagnostic capabilities. It can continuously monitor its own operational status, detect faults such as communication errors, sensor failures, and power supply issues, and generate detailed alarm messages for timely troubleshooting and maintenance.