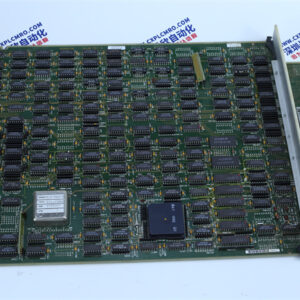

ABB S-093H 3BHB030478R0309

Product Description

The ABB S – 093H 3BHB030478R0309 is a vital phase module, which is an integral part of ABB’s ACS6000 inverter cabinet, also known as the Active Rectifier Unit (ARU). This module plays a crucial role in power conversion processes within industrial applications.

It adopts IGCT (Integrated Gate – Commutated Thyristor) technology in a self – commutating 6 – pulse, 3 – level voltage inverter configuration. Its primary function is to convert the secondary AC voltage into DC voltage. This DC voltage is then used to supply power to the capacitor in the DC circuit, ensuring that the voltage of the DC circuit remains stable. Depending on the operation mode of the motor, the ARU (the S – 093H module as part of it) can either obtain energy from the grid or inject energy back into the grid, enabling bidirectional energy flow. This feature is essential for efficient power management in industrial systems, especially those with variable – speed motor drives.

The module is designed with several functional features that enhance its performance and reliability. It has power and communication redundancy functions, which ensure continuous operation even in the event of a component failure. Hot configuration can be performed while the system is running, allowing for flexible adjustments without shutting down the entire operation. The hot swap function enables the replacement of the power supply unit during operation without interrupting the main voltage, minimizing downtime. Additionally, it offers extended diagnostics capabilities through FDT/DTM (Field Device Tool/Device Type Manager), which simplifies the configuration and troubleshooting process. Automatic diagnostics further contribute to easy maintenance, reducing the time and effort required to identify and resolve issues.

This module can be installed in non – hazardous areas or directly in Zone 1 or Zone 2 hazardous areas as part of the remote S900 I/O system with its hot swappable function.