Application Scenarios

At a natural gas compression station in Texas, false “breaker open” alarms from legacy I/O modules triggered unnecessary turbine shutdowns during lightning storms. After upgrading to the WOODWARD 9907-014. engineers leveraged its 500 V RMS channel-to-channel isolation and built-in signal filtering to eliminate noise-induced glitches. Each of the 9907-014’s 16 channels now reliably reports circuit breaker, lube oil pump, and fire-gas detector status to the MicroNet Plus CPU. During a recent grid disturbance, the system correctly ignored transient spikes while capturing a genuine low-pressure trip—preventing both nuisance shutdowns and safety compromises. “This little card restored our confidence in automated protection,” said the controls lead.

Parameter

Main Parameters Value/Description

Product Model 9907-014

Manufacturer WOODWARD

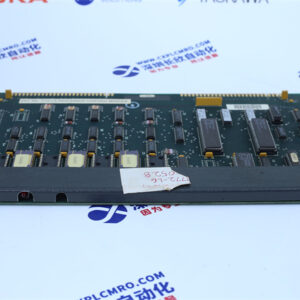

Product Category Digital Input Module (for MicroNet Plus PLC System)

Input Channels 16 isolated channels

Input Type 24 V DC (nominal), compatible with dry contacts or solid-state sources

Input Voltage Range 10–30 V DC (ON); <5 V DC (OFF)

Input Current ~3 mA per channel at 24 V DC

Response Time <2 ms typical; configurable filtering available via software

Isolation 500 V RMS between field circuits and backplane logic

Indicators 16 green LEDs (one per channel) + module status LED

Power Supply Supplied via MicroNet Plus backplane (no external power required)

Mounting Method DIN rail within MicroNet Plus chassis (35 mm standard)

Operating Temperature -20°C to +70°C

Certifications CE, UL 61010-1. CSA, IEEE 1613 (for substation EMI immunity)

Technical Principles and Innovative Values

• Innovation Point 1: True Per-Channel Isolation – Unlike cost-reduced I/O cards that share common grounds, the 9907-014 provides full galvanic isolation on every input channel. This prevents ground loops and ensures a fault on one sensor (e.g., shorted cable) doesn’t affect other signals—a critical advantage in large turbine skids with mixed-voltage devices.

• Innovation Point 2: Noise-Immune Signal Conditioning – The 9907-014 incorporates hysteresis and programmable debounce filters (via TOOLKIT™ software), rejecting electrical transients from VFDs, relays, or lightning without sacrificing response speed for real trips.

• Innovation Point 3: Seamless MicroNet Plus Integration – As a native module, the 9907-014 auto-enumerates on the backplane, requires no IP configuration, and updates all 16 inputs within the system’s deterministic scan cycle (<1 ms)—ensuring tight synchronization with control logic.

• Innovation Point 4: Hot-Swap Ready with Diagnostics – In redundant systems, the 9907-014 can be replaced live. The CPU detects removal/reinsertion and logs channel health, including open-circuit and short-circuit faults—enabling predictive maintenance before failures occur.

Application Cases and Industry Value

A European district heating plant retrofitted its steam turbine control system with a WOODWARD MicroNet Plus platform, using multiple 9907-014 modules to monitor valve limit switches, condensate pump status, and emergency stop buttons. During commissioning, the 9907-014’s per-channel LEDs allowed technicians to verify wiring in minutes—versus hours with legacy systems. Over two winters of operation, zero false trips were recorded, even during grid switching events. The plant extended its mean time between failures (MTBF) by over 40%, directly attributing reliability gains to the signal integrity of the 9907-014.

Related Product Combination Solutions

• 5437-1067A: MicroNet Plus CPU module that processes inputs from 9907-014

• 9907-015: 16-channel digital output module—ideal companion for control commands

• 9907-1200: Analog/speed I/O module for complementary signal types

• TOOLKIT™ Software: Used to configure filtering, naming, and diagnostics for 9907-014

• 9907-018: High-voltage digital input variant (suitable for 48–125 V DC systems)

• 9910-0101: Redundant chassis supporting dual 9907-014 modules in critical loops

• 5466-670: Magnetic speed sensor often used alongside 9907-014 for full turbine monitoring

• 9907-1600: Mixed I/O module combining digital inputs/outputs for compact panels

Installation, Maintenance, and Full-Cycle Support

Installing the WOODWARD 9907-014 is as simple as sliding it into an energized MicroNet Plus backplane—power and communication are handled automatically. Field wiring connects to removable screw terminals labeled per channel, with clear polarity markings. Shielded cables are recommended for long runs, with shields grounded at the controller end only to avoid ground loops.

For maintenance, the 9907-014 requires no calibration or routine servicing. Its solid-state design has no moving parts, and all diagnostics are accessible remotely via TOOLKIT™ or the system HMI. If a channel fails, the corresponding LED turns off or flashes, and a detailed fault code appears in the event log. Module replacement takes under three minutes in hot-swap configurations. Our technical support team provides lifecycle management, including obsolescence planning and cross-reference guidance, ensuring seamless operation for 15+ years.

Contact us for a customized solution—whether you’re building a new turbine control panel or modernizing an aging DCS, the WOODWARD 9907-014 delivers industrial-grade digital input performance with unmatched reliability, clarity, and integration simplicity.