Application Scenarios

At a municipal wastewater treatment plant in Germany, an aging biogas-fueled generator suffered from unstable speed during sludge digestion fluctuations, causing frequent grid disconnects. The original pneumatic actuator lacked precision and offered no remote monitoring. After upgrading to the WOODWARD 8200-1302. operators gained closed-loop LVDT-based position control and Modbus RTU communication with the plant’s SCADA system. Within days, speed variance dropped from ±3% to ±0.5%, and maintenance staff received early alerts on actuator drift—preventing two potential shutdowns in the first quarter. This case demonstrates how the WOODWARD 8200-1302 transforms basic prime movers into digitally aware, grid-compliant assets.

Technical Principles and Innovative Values

Innovation Point 1: The WOODWARD 8200-1302 employs adaptive gain scheduling—automatically adjusting PID parameters based on valve position—to maintain stability across the full stroke range, eliminating manual tuning during commissioning.

Innovation Point 2: Unlike analog positioners, it digitizes the entire control loop, enabling real-time diagnostics such as LVDT health, output current trends, and command-following error—accessible via Modbus registers for predictive maintenance.

Innovation Point 3: On loss of input signal, the 8200-1302 executes user-defined fail-safe actions: hold position, ramp to safe limit, or trigger alarm—critical for compliance with ISO 8528 and API 612 safety requirements.

Innovation Point 4: Its compact footprint (only 22.5 mm wide) allows dense mounting in retrofit panels where space is limited, yet it maintains full industrial EMC immunity (IEC 61000-4 Level 3).

Application Cases and Industry Value

A Southeast Asian palm oil mill integrated the WOODWARD 8200-1302 to control steam admission valves on three back-pressure turbines driving boiler feed pumps. Previously, manual throttle adjustments led to inconsistent power export during fiber moisture variations. With the 8200-1302. each turbine now responds automatically to steam header pressure via 4–20 mA signals from the DCS. Results included:

12% reduction in steam waste through tighter valve control

Elimination of manual operator intervention during shift changes

Remote calibration capability that cut commissioning time by 60%

The mill’s maintenance team particularly valued the “position error” alarm, which flagged a sticking valve stem before it caused a trip—showcasing the WOODWARD 8200-1302’s role in proactive asset care.

Related Product Combination Solutions

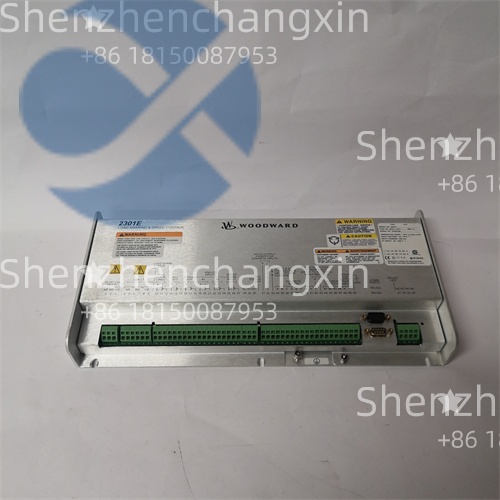

WOODWARD 2301E: Legacy electronic load/speed controller—often paired with the 8200-1302 in standalone engine-generator sets.

LVDT Sensors (e.g., Spectra Symbol SLS060): Compatible position transducers offering long-life, contactless feedback for the 8200-1302.

ABB AC 800M + CI854: DCS platform that sends 4–20 mA or Modbus setpoints to the 8200-1302 for integrated turbine control.

EMERSON ROC800: RTU that interfaces with multiple 8200-1302 units in remote compressor stations via Modbus RTU.

Hydraulic Solenoid Valves (e.g., Bosch Rexroth 4WRPE): Proportional valves directly driven by the 8200-1302’s servo output.

WOODWARD NetCon Software: Configuration tool for calibrating, trending, and updating firmware on the 8200-1302.

ROCKWELL CompactLogix + 1769-IF4XOF2F: PLC solution for local control loops using the 8200-1302 in skid-mounted systems.

WOODWARD 505: Turbine governor that outputs 4–20 mA position commands to the 8200-1302 for auxiliary valve control.

Installation, Maintenance, and Full-Cycle Support

Installation of the WOODWARD 8200-1302 begins with secure DIN-rail mounting in a ventilated control enclosure. Critical best practices include using twisted-pair shielded cables for LVDT and command signals, with shields grounded at the controller end only. Calibration is simplified through guided procedures in NetCon or front-panel push-button setup—typically requiring only two-point (min/max) stroke definition.

During operation, the 8200-1302 continuously monitors its health and logs events like overcurrent, signal loss, or excessive tracking error. These diagnostics are readable via Modbus, enabling integration into CMMS platforms for condition-based maintenance. While not hot-swappable under pressure, the unit supports quick replacement with parameter backup/restore via SD card (optional). We validate every WOODWARD 8200-1302 through thermal cycling, EMI stress testing, and full-loop functional verification. Our support includes hydraulic interface review, cybersecurity guidance for networked deployments, and lifecycle planning for plants migrating from obsolete Woodward 723 or 725 series actuators.

Contact us for a customized solution—whether you’re automating a microturbine, upgrading a diesel gen-set, or integrating valve control into a smart energy system. With deep expertise in prime mover dynamics and decades of field experience, we ensure your WOODWARD 8200-1302 delivers precision, durability, and operational intelligence.