Application Scenarios

In a 600MW coal-fired power plant, precise control of superheated steam temperature is critical for efficiency and safety. Dozens of thermocouples and pressure transmitters located on the boiler and steam lines generate 4-20 mA signals proportional to temperature and pressure. The Westinghouse 4256A84G03 modules, installed in OVATION I/O cabinets located throughout the plant, are the first point of digital conversion for these signals. Each module accepts 16 of these analog signals, conditions them, converts them to high-resolution digital values, and transmits the data to the OVATION controllers over the high-speed control network. The system logic uses this real-time data to adjust fuel, air, and spray water flows. The module’s high accuracy and reliability ensure the control system receives a true representation of the process, allowing it to maintain steam temperature within a tight band, directly impacting plant efficiency, emissions, and equipment longevity. Its failure could lead to loss of critical measurements, forcing a unit to run in a degraded or manual mode, risking safety and economic penalty.

Parameter

Technical Principles and Innovative Values

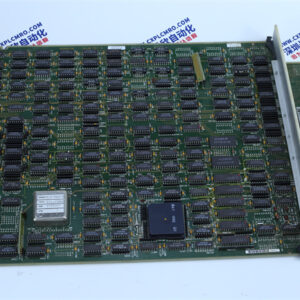

The Westinghouse 4256A84G03 embodies the core design principles of the OVATION DCS: reliability, accuracy, and modularity.

Innovation Point 1: High-Density, Intelligent Signal Conditioning. The module integrates 16 channels of precision signal conditioning, analog-to-digital conversion, and digital communication into a single, compact package. Each channel is independently conditioned with filtering and isolation to reject common-mode noise and ground loops pervasive in industrial environments. Its high-resolution ADC ensures that subtle process changes are detected and digitized with minimal error, providing the control system with the data fidelity needed for precise regulation.

Innovation Point 2: Hot-Swappability for Maximum Availability. Designed for critical 24/7 operations, the module supports hot-swapping in properly configured OVATION systems. This means a faulty or suspect module can be physically removed and replaced without powering down the controller or the associated I/O bus. This feature is paramount for power plants, where unscheduled downtime costs hundreds of thousands of dollars per hour. Maintenance can be performed during normal operation, significantly boosting overall system availability.

Innovation Point 3: Seamless Integration with OVATION Architecture. The module is not a standalone device; it is a fully integrated component of the OVATION ecosystem. It communicates with the controller via a dedicated, high-speed backplane. Its configuration (range, alarm limits, filtering) is managed entirely through the OVATION Engineer Workstation software. This deep integration simplifies engineering, ensures consistent database management, and provides powerful diagnostic tools, allowing for predictive maintenance based on module health data.

Innovation Point 4: Robust Environmental Design. Built to withstand the electrical and environmental conditions of a power plant, it features robust EMI/RFI protection, operates over a wide temperature range, and is designed for high mean time between failures (MTBF). This ruggedness ensures long-term stability in the presence of vibration, temperature swings, and electrical interference.

Application Cases and Industry Value

Case Study: Nuclear Power Plant Safety System Monitoring. In a nuclear power plant, the reliability of safety-related measurements is non-negotiable. Multiple Westinghouse 4256A84G03 modules are used in diverse safety and non-safety systems. For instance, they might be deployed in the primary coolant pressure monitoring loops. The modules’ high accuracy ensures that pressure readings fed to the control and safety systems are trustworthy. Their isolation prevents faults in one channel from affecting others. During a planned outage, a routine diagnostic flagged a potential drift on one channel of a 4256A84G03. Because the module is hot-swappable, it was replaced preemptively without impacting the operational readiness of other systems. This proactive replacement, guided by the system’s diagnostics, exemplifies the value of intelligent, maintainable I/O in achieving the ultimate goal of nuclear safety: preventing incidents through predictive maintenance and fault tolerance.

Case Study: Combined Cycle Gas Plant Efficiency Optimization. A modern combined cycle plant uses the OVATION DCS to maximize heat rate efficiency. Dozens of 4256A84G03 modules measure exhaust gas temperatures, fuel gas pressures, and steam conditions at multiple points in the Heat Recovery Steam Generator (HRSG). The high-accuracy data from these modules allows the advanced process control algorithms to fine-tune the gas turbine and steam turbine loads in unison. A failure of one of these modules could lead to suboptimal control, costing the plant thousands of dollars per day in lost efficiency. The plant’s strategy of holding critical spares like the 4256A84G03 and training staff on rapid, hot-swap procedures minimizes the duration of any measurement loss, directly protecting revenue and ensuring the plant can respond quickly to grid dispatch signals.

Related Product Combination Solutions

The 4256A84G03 operates as part of a complete OVATION I/O subsystem.

OVATION Controller (e.g., a specific controller model): The brain of the system. The 4256A84G03 module plugs into an I/O baseplate that communicates with this controller.

I/O Baseplate / Carrier: The physical assembly mounted in the I/O cabinet that provides power, communication, and the slot for the 4256A84G03 module. (e.g., 1C31129G01 or similar).

Field Termination Assembly (FTA): A separate termination panel (e.g., 1C31117G01) that mounts on the cabinet door. Field wiring lands on the FTA’s screw terminals, which is then connected to the 4256A84G03 module via a ribbon cable. This separates sensitive electronics from field wiring connections.

Power Supply Module: Provides the isolated and conditioned power required for the I/O modules (e.g., 5X00097G01).

OVATION Engineer/Operator Workstation: The software environment (running on servers and workstations) where the 4256A84G03 is configured, its signals are tagged, and its health is monitored.

Other I/O Modules (e.g., Analog Output 4256A85G03. Digital Input, etc.): A complete control loop requires different module types. The AI (4256A84G03) provides the measurement, the controller computes, and an Analog Output (AO) module sends the command to a valve.

Installation, Maintenance, and Full-Cycle Support

Installation is performed by qualified personnel. The module is inserted into its designated slot on the powered I/O baseplate until it clicks into place. The corresponding ribbon cable from the Field Termination Assembly (FTA) is then connected. Configuration is entirely software-based using the OVATION engineering tools, where the engineer defines the signal type (4-20mA, etc.), engineering units, scaling, and alarm limits for each channel.

Routine maintenance involves monitoring the module’s health via the OVATION diagnostics, which can report issues like channel failures, communication errors, or out-of-spec conditions. The status LEDs on the module provide immediate local indication (Power OK, Module OK, Channel activity).

Troubleshooting typically involves using system diagnostics to isolate a problem. If a channel fails, the signal can be checked at the FTA. If the module itself is suspected, and the system supports it, it can be hot-swapped: 1) The system will typically recognize the removal. 2) The technician releases the locking lever, extracts the old module, and inserts a new, pre-configured one. 3) The system automatically recognizes the new module and resumes operation. Caution: Hot-swap procedures must be followed precisely as per plant safety and OVATION manuals.

We provide full-cycle support for the Westinghouse 4256A84G03 and the broader OVATION ecosystem. This includes:

Supply: Providing new, refurbished, or guaranteed-working spare modules.

Testing: Pre-shipment testing to ensure functionality.

Configuration: Assisting with or confirming software configuration details.

Technical Support: Guidance on installation, troubleshooting, and integration.

Lifecycle Management: Advising on migration paths or compatible alternatives as systems evolve.

Need a reliable source for OVATION DCS spares like the 4256A84G03 to ensure your plant’s operational continuity? Contact us for expert support, guaranteed products, and comprehensive lifecycle services.