Application Scenarios

In a combined-cycle gas turbine power plant, the health of the multi-ton gas and steam turbine rotors is paramount. A failure can cause months of downtime and tens of millions in damage. The WESTINGHOUSE 4256A84G02 modules are installed in the turbine control room’s rack-mounted monitoring system. Each module is connected to a key radial vibration probe on the turbine bearings. It continuously monitors the probe’s gap voltage, converting it into a precise vibration measurement in mils or microns peak-to-peak. During a cold start, an operator watches the trend on the HMI. If vibration on the #3 bearing begins to rise abnormally due to a temporary thermal bow, the 4256A84G02 module provides a stable, accurate reading. Its calibrated circuitry triggers a “High Alert” warning on the control screen long before reaching the dangerous “High-High Trip” level, giving the operator time to stabilize the unit. This solves the critical problem of predicting and preventing mechanical failure, allowing for scheduled intervention rather than emergency shutdowns.

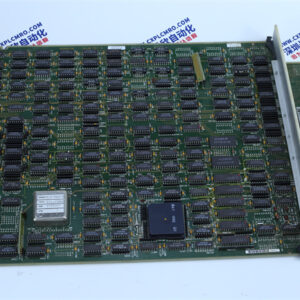

Parameter

Technical Principles and Innovative Values

This module embodies core principles of reliable machinery protection, translating physical motion into actionable data.

Innovation Point 1: Precision Signal Conditioning for Eddy-Current Probes. The module’s core is a sophisticated signal conditioner tailored for eddy-current probes. It supplies the probe with a precise high-frequency oscillation current and demodulates the returning signal, which is modulated by the distance (gap) to the metal target (shaft). It filters out electrical noise and converts the gap voltage into an accurate DC signal representing vibration displacement. This requires stable, temperature-compensated circuitry to maintain calibration over years of service.

Innovation Point 2: Dual-Threshold Alarm with Hysteresis. The module provides two independent, field-adjustable setpoints: an Alert (warning) and a Danger (trip) level. Each setpoint activates a relay. Crucially, these alarms incorporate hysteresis, meaning the signal must fall a certain amount belowthe setpoint to de-energize after tripping. This prevents relay “chatter” if the vibration hovers right at the alarm limit, a critical feature for system stability.

Innovation Point 3: System Integration and Diagnostics. It is designed not as a standalone unit but as part of a coordinated protection system. Its scaled 4-20 mA output allows trending in the plant DCS/PLC, while its buffered raw signal output can be routed to a separate diagnostic data collector for spectrum analysis. Front-panel indicators provide immediate health status, and the module is often “hot-swappable” in its rack, allowing replacement without shutting down the monitored machine.

Application Cases and Industry Value

Case Study: Petrochemical Refinery Centrifugal Compressor Protection. A critical hydrogen recycle compressor in a refinery, worth over $5 million, began exhibiting slowly rising vibration. The WESTINGHOUSE 4256A84G02 monitoring its drive end bearing provided the trend data. The alert was triggered, and maintenance was scheduled. During inspection, early stages of impeller fouling were found. The unit was cleaned during a planned turnaround, avoiding an unplanned trip that would have caused a full refinery shutdown costing over $1 million per day. The module’s reliable, accurate signal provided the confidence needed to make informed operational decisions, directly enabling predictive maintenance.

Case Study: Legacy Power Plant Life Extension. A 40-year-old coal-fired power plant extending its life faced the challenge of obsolete monitoring systems. Spare parts for the original turbine TSS, including the 4256A84G02 cards, were scarce. One card developed a fault, causing a false vibration trip and a costly unit outage. The plant sourced a refurbished and certified 4256A84G02 from a specialized supplier. The module was swapped in, calibrated on-site using a portable calibrator, and the system was restored to service. This allowed the plant to maintain its existing, well-understood protection architecture for several more years, deferring a multi-million-dollar system-wide upgrade and ensuring continued reliable operation for the remaining plant life.

Related Product Combination Solutions

The 4256A84G02 is a single component in a comprehensive protection and monitoring system.

Eddy-Current Proximity Probes (e.g., Bently Nevada 3300 XL 8mm): The sensors that measure shaft vibration and provide the raw signal to the 4256A84G02 monitor.

Probe Extension Cables & Connectors: Specialized coaxial cables that connect the probe to the monitor, preserving signal integrity.

System Rack / Power Supply (e.g., Westinghouse Frame): The chassis that houses multiple monitoring modules (vibration, speed, axial position), provides common power, and consolidates alarm relays.

Keyphasor® Module: A companion module that accepts a once-per-revolution pulse from a separate probe. This timing reference is essential for determining vibration phase and speed, used alongside vibration modules for balancing and diagnostics.

Axial Position Monitor Module: A different card in the same rack that monitors thrust bearing wear.

PLC or DCS Interface: The plant’s main control system that receives the 4-20mA signals and relay contacts from the 4256A84G02 for logging, display, and initiating unit trips.

Diagnostic Data Manager: A separate system that collects the buffered raw vibration signals from all monitors for advanced analysis (FFT, trends, etc.).