Application Scenarios

At a liquefied natural gas(LNG)export terminal in Australia,a turbine overspeed event threatened catastrophic mechanical failure.The legacy safety system—based on a non-redundant PLC—took 850 ms to trip.After upgrading to a TRICON 4000094-310-based SIS,the same scenario triggered a shutdown in<120 ms,well within the turbine manufacturer’s 200 ms limit.During the incident,one of the three processor lanes detected a transient memory error,voted it out in real time,and maintained full control—proving the system’s ability to operate through faults.Over three years,the facility recorded zero spurious trips and 100%proof test success,directly attributable to the 4000094-310’s fault-masking capability.In this context,the module wasn’t just processing logic—it was preventing a potential billion-dollar disaster.

Parameter

Main Parameters Value/Description

Product Model 4000094-310

Manufacturer TRICONEX/Schneider Electric

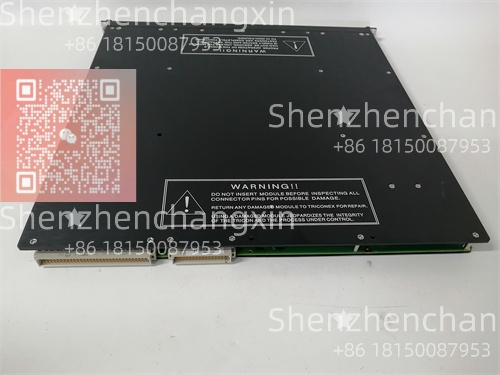

Product Category TMR Main Processor Module(CPU)

Architecture Triple-Modular Redundant(3oo3 with 2oo3 voting)

Processor Three independent 32-bit RISC CPUs with synchronized execution

Memory Flash-based application storage;SRAM with ECC for runtime data

Scan Time As low as 10 ms(configurable based on application size)

Diagnostic Coverage>99.9%(per IEC 61508)–includes memory,I/O,communication,power

Hot-Swap Capable Yes–supports replacement without system shutdown(in redundant chassis)

Operating Temperature 0°C to+60°C

Safety Certification IEC 61508 SIL 3,ANSI/ISA 84.01,API RP 14C,ATEX(system-level)

Communication Proprietary Tricon bus to I/O modules;Modbus/TCP via optional comms cards

Technical Principles and Innovative Values

Innovation Point 1:Hardware-Enforced TMR from Input to Output

Unlike software-redundant PLCs,the 4000094-310 implements redundancy at every layer—processors,memory,power,and internal buses—with continuous cross-comparison ensuring no single fault can cause a dangerous failure.

Innovation Point 2:Zero-Overhead Fault Masking

The integrated voter circuit isolates faulty lanes in nanoseconds—without interrupting scan cycles or requiring application intervention—enabling true“fail-operational”behavior.

Innovation Point 3:Comprehensive Built-In Test(BIT)

On power-up and continuously during operation,the 4000094-310 runs>200 diagnostic routines,including memory walking-bit tests,watchdog timers,and clock integrity checks—logging all results for audit.

Innovation Point 4:Deterministic Execution for Fast Shutdown

With fixed-cycle scanning and priority interrupt handling,the 4000094-310 guarantees worst-case response times—critical for turbine overspeed or reactor runaway scenarios.

Application Cases and Industry Value

In a U.S.Gulf Coast refinery,a hydrocracker unit required a SIL 3-compliant SIS to meet PSM regulations.The TRICON 4000094-310 was deployed to manage 120+ESD valves and sensors.During a major turnaround,operators performed online diagnostics using TriStation 1131,identifying a marginal I/O module before it failed—avoiding a potential$5M/day production loss.Over five years,the system achieved 99.999%availability,with zero missed trips during 17 process excursions.

Another case involved a geothermal power plant in Iceland,where volcanic sulfur corrosion degraded conventional controllers.The 4000094-310,housed in a NEMA 4X cabinet,operated reliably for 8+years despite H₂S exposure—thanks to conformal-coated PCBs and sealed connectors specified in the Tricon system design.

![]()

![]()