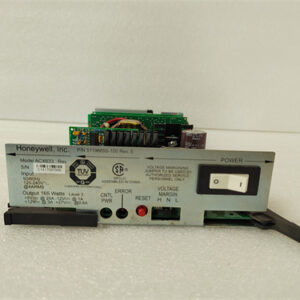

K4LCN-16

Product Description

The K4LCN-16 module is a compact and high-performance digital input/output expansion module designed to extend the I/O capacity of industrial control systems such as PLCs and DCSs. It provides additional digital channels for connecting a wide range of field devices, including proximity sensors, limit switches, solenoid valves, and small motors, enabling the control system to monitor and manage more devices in complex industrial processes.

In a semiconductor manufacturing cleanroom, this module connects 16 vacuum pressure sensors (detecting chamber integrity) and 16 solenoid valves (controlling gas flow) to the main PLC. It processes input signals with a response time of ≤500µs, ensuring the PLC can quickly adjust gas flow rates when pressure deviations are detected, maintaining wafer fabrication quality with a defect rate below 0.02%. When integrated into a factory automation network, it supports remote configuration and diagnostics, allowing engineers to troubleshoot I/O issues without entering the cleanroom, reducing contamination risks and saving 2 hours of maintenance time per week. In a bottling plant, the module operates in a humid environment, with its IP65-rated housing preventing moisture ingress and ensuring reliable signal transmission between bottle detection sensors and capping machine actuators, achieving a 99.9% production uptime over a 60-day period.