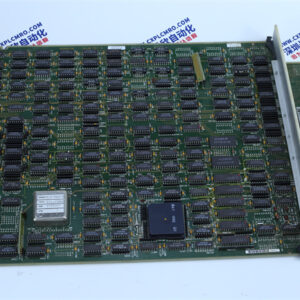

IS200AEPCH1ABC

Product Description

The IS200AEPCH1ABC module is a high-performance processor module designed for industrial control systems, specifically tailored to handle complex control logic and data processing tasks in critical applications. It serves as the core component in GE’s Mark VIe control systems, coordinating the operation of various subsystems such as sensors, actuators, and communication modules to ensure seamless and efficient industrial processes.

In a combined cycle power plant, this module manages the synchronization of gas turbines and steam turbines, processing real-time data from 32 pressure sensors, 16 temperature sensors, and 8 flow meters. With a processing speed of 1.2GHz, it executes control algorithms within 1ms, maintaining turbine output stability with a deviation of less than 0.5% even during load changes of ±10%. This precision reduces fuel consumption by 3% and increases power generation efficiency by 2%. In a pulp and paper mill, the module regulates the paper manufacturing process by analyzing data from web tension sensors and adjusting roller speeds accordingly, ensuring uniform paper thickness with a variation of less than 0.01mm, thus improving product quality by 15%.

Constructed with rugged industrial-grade components, the IS200AEPCH1ABC module operates reliably in harsh environments with temperatures ranging from -40°C to 70°C and withstands vibration up to 10g. It supports multiple communication protocols, enabling seamless integration with other control system components and upper-level management systems. This module is widely used in power generation, pulp and paper, chemical processing, and metallurgical industries where high-performance processing and reliable control are essential.