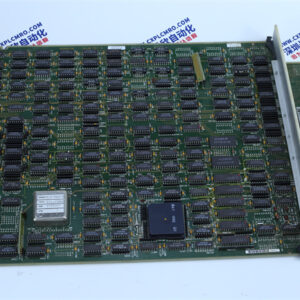

GFD563A102 3BHE046836R0102

The product is named the GFD563A102 3BHE046836R0102 module. It is a component in the field of industrial control and automation, manufactured by ABB, a renowned company in the industrial technology sector.

2. Product Description

2.1 General Function

The GFD563A102 3BHE046836R0102 is an interface module. It is designed to interface with excitation and convection systems, playing a vital role in providing control and monitoring functions. In industrial setups, especially those related to power generation and large – scale machinery operations, it acts as a bridge between different subsystems. For example, in a power plant’s generator excitation system, it can receive signals related to the generator’s operating conditions, such as voltage and current levels, and based on pre – set algorithms, it can adjust the excitation current to maintain stable voltage output. It also monitors the performance of the convection cooling system associated with the generator, ensuring that the equipment operates within the optimal temperature range.

2.2 Applications

- Power Generation Industry: In thermal power plants, hydroelectric power plants, and nuclear power plants, the GFD563A102 module is widely used in generator excitation systems. It helps in regulating the excitation current of the generator, which is crucial for maintaining the stability of the power grid. For instance, during peak – load periods, the module can adjust the excitation to increase the generator’s output voltage, ensuring a stable power supply. In hydroelectric power plants, it can also work in tandem with the water – turbine control system to optimize power generation efficiency.

- Industrial Machinery: In large – scale industrial machinery, such as high – power motors in mining equipment or large – capacity compressors in the petrochemical industry, the module can be used to monitor and control the cooling systems. These machines generate a significant amount of heat during operation, and the convection – cooling systems need to be precisely controlled. The GFD563A102 module can monitor the temperature of the machinery components and adjust the flow rate of the cooling medium (such as air or liquid) through the convection system to keep the temperature within the safe operating range. This helps in preventing overheating, which could lead to equipment failure and production disruptions.

2.3 Features

- High – Reliability Design: The module is engineered with high – quality components and advanced manufacturing techniques, ensuring high reliability in operation. It can withstand harsh industrial environments, including high temperatures, high humidity, and electrical interference. This makes it suitable for use in various industrial settings where equipment reliability is of utmost importance.

- Modular Design: Its modular design allows for easy integration into existing industrial control systems. It can be easily installed, removed, or replaced without significant disruption to the overall system. This modularity also enables system expansion and upgrade. For example, if an industrial plant decides to add more monitoring or control functions to its power – generation equipment, the GFD563A102 module can be added to the existing control system with relative ease.

- Flexible Configuration: The GFD563A102 module offers flexible configuration options. Users can adjust its settings according to the specific requirements of their applications. For example, the input and output parameters can be configured to match the characteristics of the connected excitation and convection systems. This flexibility makes it adaptable to a wide range of industrial scenarios.

3. Product Parameters

- Electrical Parameters:

- Operating Voltage: It typically operates at 220V, which is a common voltage level in many industrial power supplies. However, it may have a certain tolerance range to accommodate minor voltage fluctuations in the industrial power grid, usually within ±10% of the nominal value.

- Output Frequency: The module has an output frequency of 60KHZ. This frequency is suitable for driving and controlling the relevant components in the excitation and convection systems, ensuring smooth and stable operation.

- Mechanical Parameters:

- Dimensions: The product has a net depth/length of 380 millimeters, a net height of 73.5 millimeters, and a net width of 142 millimeters. These dimensions are designed to fit standard industrial enclosures and control cabinets, facilitating installation and integration into existing industrial setups.

- Weight: It has a net weight of 1.54 kilograms. A relatively lightweight design is beneficial for easy handling during installation and maintenance processes in the industrial environment.

- Interface Parameters:

- Communication Interfaces: The module is likely to be equipped with standard communication interfaces such as RS – 485 or Ethernet. These interfaces enable seamless communication with other components in the industrial control network, such as programmable logic controllers (PLCs), human – machine interfaces (HMIs), and other monitoring and control devices. For example, through the RS – 485 interface, it can transmit real – time monitoring data to a PLC for further processing and control.

4. Product Specifications

- Model: GFD563A102 3BHE046836R0102

- Manufacturer: ABB

- Product Type: Interface module for excitation and convection systems

- Environmental Specifications:

- Operating Temperature Range: It can operate within a temperature range of – 20 °C to 60 °C. This wide temperature tolerance allows it to be used in various industrial environments, from cold storage facilities to hot manufacturing plants. However, in extreme temperature conditions, additional cooling or heating measures may be required to ensure optimal performance.

- Humidity Tolerance: The module can tolerate humidity levels in the range of 5% to 95% non – condensing. High humidity can cause corrosion and electrical problems in electronic components, but the module is designed with materials and construction techniques to resist such effects. In industrial environments near water sources or with high ambient humidity, such as in some food and beverage processing facilities or near coastal areas, the module can still operate reliably as long as there is no formation of water droplets on its surface.

- Compatibility: The GFD563A102 3BHE046836R0102 module is designed to be compatible with other components in ABB’s industrial control product range, as well as with some third – party industrial control equipment. This compatibility simplifies the integration process in industrial control systems, allowing users to choose components from different sources to build a customized control solution that meets their specific requirements.