Application Scenarios

In a large chemical processing plant undergoing a capacity expansion,engineers faced a common yet costly dilemma:late-stage design changes required converting several pressure monitoring points(analog inputs)into flow control loops(requiring analog outputs).With traditional fixed-function I/O cards,this would have meant weeks of delay for procurement and re-wiring.However,the plant’s control system was built on the I/A Series platform utilizing the FOXBORO P0911QB.The solution was remarkably efficient.Engineers simply accessed the I/A Series workstation software,reconfigured the necessary channels on the existing P0911QBmodules from input to output mode,and updated the control logic.The hardware remained unchanged.This software-defined flexibility prevented project delays,avoided unnecessary hardware costs,and demonstrated the module’s core value in adapting to dynamic project needs.The P0911QBdirectly addressed the pain points of design rigidity and long lead times,turning a potential setback into a seamless configuration change.

Parameter

Here are the key technical specifications for the FOXBORO P0911QBmodule:

Main Parameters

Value/Description

Product Model

P0911QB

Manufacturer

Foxboro(Emerson)

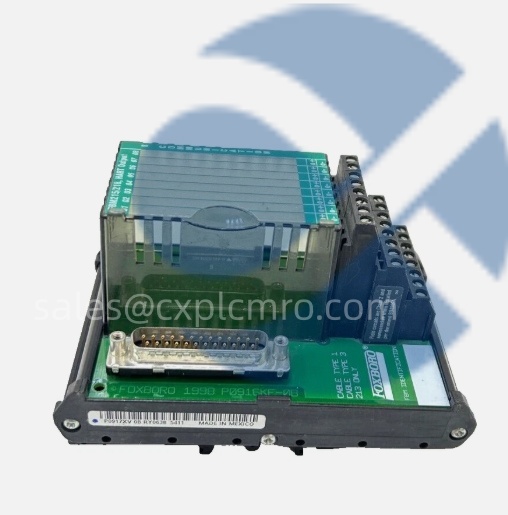

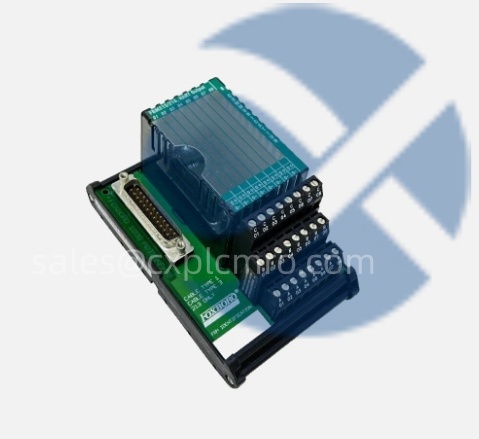

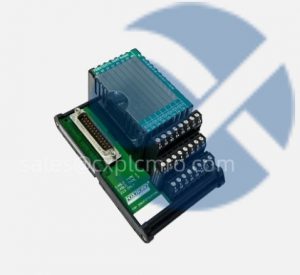

Product Category

Analog Input/Output Fieldbus Module(FBM)

Channels

8 channels,individually software-configurable

Signal Types

4-20mA Input(Sink),4-20mA Output(Source)

Resolution

16-bit(Provides high-fidelity signal conversion)

Accuracy

±0.1%of span(Ensures precise control and monitoring)

Isolation

Channel-to-Channel and Channel-to-Bus Isolation(Prevents ground loop issues and noise interference)

Input Impedance

250 Ohms

Load Compliance(Output)

Up to 750 Ohms

Power Supply

Powered via the FBM backplane(Typically 5V DC from the FBM)

Operating Temperature

-40°C to 70°C(-40°F to 158°F)(Suitable for harsh environments)

Communication

Foxboro I/A Series Native Fieldbus to FBM Controller

Technical Principles and Innovative Values

The FOXBORO P0911QBis engineered around principles of flexibility,reliability,and integration,offering distinct advantages in the DCS landscape.

Innovation Point 1:Software-Defined Channel Functionality

The most significant innovation of the P0911QBis its per-channel software configurability.Unlike fixed-function modules,it acts as a universal analog interface.This is achieved through intelligent circuit design and firmware that allows the onboard microprocessor to reconfigure signal conditioning paths digitally.This reduces the number of distinct part numbers needed in inventory by at least half,transforming capital planning and sparing strategy.

Innovation Point 2:Integrated Diagnostics and Signal Integrity

The module incorporates advanced diagnostics that are transparent to the control system.For input channels,it continuously monitors for open-circuit conditions.For output channels,it can detect load-related issues.This proactive fault detection,combined with high-grade optical and transformer-based isolation,ensures signal integrity in electrically noisy industrial environments and enables predictive maintenance,reducing unplanned downtime.

Innovation Point 3:Seamless Ecosystem Integration

The P0911QBis not a standalone device but a deeply integrated component of the I/A Series DCS.Its configuration,calibration,and extensive diagnostic data are fully accessible and manageable from the unified I/A Series workstation software.This deep integration simplifies engineering,reduces training overhead,and provides a single pane of glass for system health,from the field sensor to the control algorithm.

Innovation Point 4:Ruggedized Industrial Design

Built to withstand extreme temperatures,vibration,and electromagnetic interference,the P0911QBuses high-quality,industrial-grade components.Its wide operating temperature range allows deployment in non-climatized field enclosures closer to process equipment,reducing wiring costs and improving signal quality over long runs.

Application Cases and Industry Value

Case Study 1:Modernization of a Gulf Coast Refinery

A major refinery in the US Gulf Coast was modernizing its crude distillation unit control system,migrating from older pneumatic controls to a modern Foxboro I/A Series DCS.The project involved thousands of I/O points.Engineers standardized on the FOXBORO P0911QBfor the majority of analog signals due to its flexibility.During commissioning,several last-minute piping and instrumentation diagram(P&ID)changes required swapping signal types.Instead of waiting for new hardware,the team reconfigured over 50 channels on the fly using the software.The project manager reported that the use of the P0911QBcontributed to the project finishing 5%under budget and one week ahead of schedule,directly attributable to reduced hardware change orders and accelerated commissioning.

Case Study 2:Reliability in a Remote Canadian Power Plant

A combined-cycle power plant in a remote location of Canada relied on its I/A Series DCS for base-load operation.Maintaining a lean but comprehensive spare parts inventory was critical due to long supply chains.The plant standardized on the P0911QBas its sole analog I/O spare for non-critical loops.This strategy paid off when an output module failed on a weekend.The maintenance team replaced it with a P0911QBfrom stock,reconfigured it in 15 minutes,and restored the feedwater control loop without waiting for a specialized part to be flown in.The plant engineer highlighted that this flexibility turned a potential 48-hour outage into a 30-minute downtime,showcasing the module’s value in ensuring operational continuity and reducing mean time to repair(MTTR).

Related Product Combination Solutions

A functional I/A Series node utilizing the P0911QBrequires several complementary components.Here are key related models:

FBM Controller(e.g.,FBMxxx series):The parent controller that houses the application logic and communicates with the P0911QBmodules over the fieldbus.The P0911QBis useless without it.

FBM Base/Backplane(e.g.,components for mounting):The physical enclosure and connector that provides power and communication to the P0911QBmodule.

Redundant FBM Pair:For critical applications,the P0911QBcan be deployed in a redundant pair with another P0911QB,ensuring automatic switchover and zero downtime in case of a hardware fault.

Other FBM Types(e.g.,FBM P0911QH-Digital I/O,FBM P0911QA-Pulse Input):A complete system uses a mix of I/O types.These modules mount on the same backplane,allowing a single controller to handle analog,digital,and specialty signals.

Field Wiring Assemblies&Terminals:Specific terminal blocks and harnesses(often Foxboro-specific part numbers)are required for proper and reliable connection of field wiring to the P0911QB.

Power Supply Module:A stable,clean DC power supply unit is essential for the FBM rack that houses the controllers and I/O modules like the P0911QB.

I/A Series Workstation Software:The configuration,monitoring,and diagnostic platform for the entire system,including all P0911QBmodules.

Installation,Maintenance,and Full-Cycle Support

Installation and commissioning of the FOXBORO P0911QBare designed for efficiency.The module is hot-swappable in systems configured for redundancy,allowing for replacement without a system shutdown.Installation involves securing the module into its designated slot on the FBM base unit until it clicks into place—no tools are required.The critical preparatory step is ensuring the FBM base is properly powered and addressed within the I/A Series control network.Field wiring should adhere to industry standards for analog signals:using twisted-pair shielded cables,with the shield grounded at the control panel end only to minimize noise.

Routine maintenance is minimal due to the solid-state design.The primary focus is on preventive monitoring through the I/A Series workstation software,which provides continuous health status,diagnostic alerts,and signal quality indicators for each channel of the P0911QB.In the event of a module failure,diagnostics will pinpoint the issue.Replacement is straightforward:download the configuration from the old module or the control database,swap the hardware,and upload the configuration to the new P0911QB.It is crucial to verify firmware version compatibility with the host controller during replacement.

We provide comprehensive lifecycle support for the FOXBORO P0911QB.Our units are sourced from reliable channels and undergo rigorous functional testing to ensure they meet or exceed original specifications.We offer a standard 12-month warranty and provide expert technical support to assist with compatibility verification,configuration questions,and integration challenges.Our goal is to ensure your legacy Foxboro I/A Series systems continue to operate with reliability and performance,minimizing risk and maximizing your operational uptime.

Contact us today for a customized sparing or system upgrade solution involving the reliable FOXBORO P0911QB.

选择深圳长欣,享受无忧的售后服务和高品质产品。