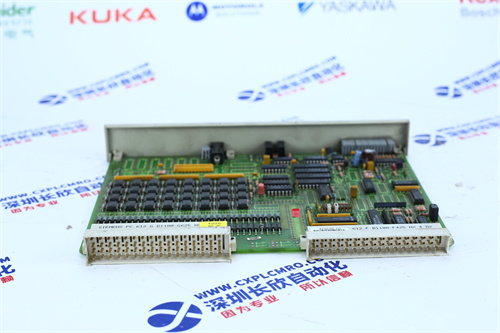

D685A1156U01

Yaskawa D685A1156U01 Servo Drive Module (Sigma-7 Series High-Power Servo Amplifier)

Product Description

The D685A1156U01 is a high-performance servo drive module from Yaskawa’s Sigma-7 series, engineered to control large-scale AC servo motors in industrial automation applications requiring precise motion control and high torque output. Its core function is to convert DC bus voltage into three-phase AC power with adjustable frequency and amplitude, driving servo motors to achieve accurate speed, position, and torque regulation—critical for applications such as heavy-duty CNC machine tools, large robotic arms, and material handling systems (e.g., controlling the main spindle of a 5-axis machining center with a positioning accuracy of ±0.001mm).

Designed for high-power applications, the module supports servo motors with a rated output of up to 22kW, delivering a continuous output current of 65A (rms) and a peak current of 195A (300% of rated for 3 seconds)—sufficient to drive motors with a maximum torque of 140N·m (e.g., in a forging press robot, enabling rapid acceleration from 0 to 3000rpm in 0.5 seconds). It utilizes Yaskawa’s proprietary Sigma-7 control algorithm, which integrates advanced features like vibration suppression (reducing residual vibration by 80% in high-speed positioning) and friction compensation, ensuring smooth operation even at low speeds (speed stability ≤±0.01% at 1rpm).

The drive supports multiple control modes: position control (via pulse train, Ethernet/IP, or Modbus TCP/IP), speed control (analog voltage or network command), and torque control (analog current command). In position control mode, it accepts pulse inputs up to 4MHz, enabling high-resolution positioning (e.g., a 10,000-line encoder motor achieves a positioning resolution of 0.036° per pulse). For networked systems, it integrates Ethernet/IP and Modbus TCP/IP interfaces, allowing seamless communication with PLCs (e.g., Allen-Bradley Logix5000) and HMIs, with data update rates as low as 1ms for real-time synchronization.