D2D146-AA28-28

Product Name

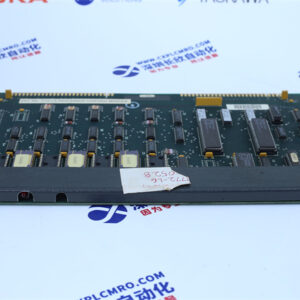

ABB D2D146-AA28-28 Variable-Frequency Centrifugal Fan Module for Industrial Thermal Management(The naming follows ABB’s industrial fan conventions:

-

-

- “D2D146”: Identifies the “D2D” series of centrifugal fans—ABB’s flagship line for equipment cooling, with “146” specifying the 146mm impeller diameter variant.

- “AA28-28”: Specifies the variable-frequency (VFD-integrated) version optimized for 28V DC input and 28m³/h nominal airflow.

- “Variable-Frequency Centrifugal Fan Module”: Highlights its dual core attributes—centrifugal airflow generation and variable-speed control for adaptive cooling.

This module acts as a “smart thermal regulator,” dynamically adjusting airflow to match equipment heat loads while minimizing energy consumption.)

-

2. Product Description

The D2D146-AA28-28 is an industrial-grade variable-frequency centrifugal fan module engineered by ABB to address core challenges in equipment thermal management: inefficient fixed-speed cooling, inadequate airflow control, and poor reliability in harsh industrial environments. As a key component of ABB’s thermal management ecosystem, it integrates VFD-based speed adjustment, high-static-pressure airflow, and ruggedized construction—making it indispensable for:

-

-

- Power Electronics: Cooling inverters, rectifiers, and frequency drives in solar inverters, wind turbine converters, and industrial motor control centers (MCCs) 。

- Telecommunications: Managing heat in outdoor base stations, server racks, and data center UPS systems.

- Heavy Industry: Ventilating control cabinets, PLC panels, and sensor enclosures in steel mills, oil refineries, and manufacturing plants.

-

Key Functional Advantages

-

-

Variable-Frequency Speed Control for Energy EfficiencyEquipped with an integrated variable-frequency drive (VFD) that adjusts fan speed from 1,500 to 4,500 RPM , enabling airflow modulation from 8 to 28m³/h. This adaptive control reduces energy consumption by 30–50% compared to fixed-speed fans—critical for 24/7-operated equipment like data center UPS systems (saving $1,200+/year in electricity costs per unit) 。

-

High-Static-Pressure Design for Enclosed SpacesFeatures a backward-curved centrifugal impeller optimized to generate 150–350 Pa static pressure , ensuring effective airflow through dense heat sinks, dust filters, and long ductwork. In solar inverter cabinets, this design maintains component temperatures 10–15°C lower than axial fans, extending capacitor lifespan by 2+ years.

-

Rugged Construction for Industrial DurabilityBuilt to withstand harsh operating conditions:

- Wide Temperature Range: Operates from -40°C to +70°C , adapting to unconditioned outdoor enclosures and desert/arctic environments.

- Corrosion Resistance: Galvanized steel housing and IP54-rated protection shield against dust, moisture, and industrial contaminants (e.g., oil mist in refineries).

- Vibration Dampening: Rubber mounting feet reduce operational vibration by 60% , preventing noise propagation and structural wear in control cabinets.

-