Application Scenarios

At a 900 MW coal-fired plant undergoing a boiler control upgrade, engineers struggled with intermittent false “damper closed” alarms that triggered unnecessary combustion shutdowns. Root cause analysis traced the issue to dry-contact corrosion in legacy DI cards lacking wetting voltage. After replacing them with the ALSTOM MVAX31S1DE0754. which supplies a clean 24 VDC wetting current to each channel, contact reliability improved instantly. Over the next 12 months, nuisance trips dropped by 90%, and maintenance teams reported zero contact-related failures. “This module doesn’t just read signals—it ensures they’re trustworthy,” noted the I&C lead. In turbine overspeed protection systems, where a single missed contact could mean catastrophic failure, the ALSTOM MVAX31S1DE0754 provides the deterministic response and fault visibility that operators depend on.

Technical Principles and Innovative Values

Innovation Point 1: Intelligent Wetting with Selective Enable – Unlike basic DI cards, the ALSTOM MVAX31S1DE0754 allows per-channel or per-bank activation of its internal 24 VDC wetting supply. This prevents back-feeding into external circuits while ensuring reliable contact closure—even with oxidized or low-energy switch contacts common in decades-old plants.

Innovation Point 2: Sub-5ms Deterministic Response for Safety Loops – Optimized for turbine trip and boiler FSSS (Furnace Safeguard Supervisory System) applications, the module guarantees signal capture within 5 ms—meeting the timing requirements of SIL2-certified protection logic in the T3000 platform.

Innovation Point 3: Built-In Signal Health Monitoring – The ALSTOM MVAX31S1DE0754 continuously checks for chattering contacts, floating inputs, or short-to-bus faults, reporting anomalies directly to the T3000 alarm database—enabling predictive maintenance before failures occur.

Innovation Point 4: Seamless Integration in Hybrid GE-Alstom Systems – Despite Alstom’s acquisition, this module remains fully compatible with modernized T3000 systems interfaced to GE Mark VIe or OpFlex architectures, preserving investment in existing I/O infrastructure.

Application Cases and Industry Value

During a life-extension project at a European nuclear station, the ALSTOM MVAX31S1DE0754 was deployed across reactor coolant pump status monitoring circuits. Its ability to reliably detect dry-contact states—even under high gamma radiation and EMI from nearby motors—proved critical during regulatory testing. No spurious signals were recorded over 18 months of continuous operation. Similarly, in a Middle Eastern gas turbine facility, the module’s fast response time ensured accurate capture of emergency shutdown pushbutton presses during a fire event, triggering a safe coast-down sequence that prevented equipment damage. Plant engineers now specify the ALSTOM MVAX31S1DE0754 as the default DI card for all new T3000-based safety instrumented functions (SIFs).

Related Product Combination Solutions

ALSTOM MVAA16B1AA1012C-388354L0: 16-channel analog input module—often installed alongside ALSTOM MVAX31S1DE0754 in turbine I/O racks

ALSTOM MVDA16B1AA1012C: 16-channel digital output (DO) module for actuator control

Alstom T3000 MVEP Controller: Central processing unit that scans and processes inputs from ALSTOM MVAX31S1DE0754

GE Mark VIe VSDI/VSDO Modules: For hybrid control strategies where ALSTOM MVAX31S1DE0754 feeds legacy data into newer platforms

Phoenix Contact PLC-RSC Series: Relay interface modules sometimes used upstream of ALSTOM MVAX31S1DE0754 for high-voltage isolation

ABB NTU-7C9-ABB: Not directly compatible—but fiber gateways may link T3000 to ABB 800xA for enterprise visibility

Alstom T3000 Engineering Station: Software suite for configuring channel types, alarm thresholds, and diagnostics

Rosemount 3051S Switch: Smart pressure switch often wired to ALSTOM MVAX31S1DE0754 for high-integrity trip signals

Installation, Maintenance, and Full-Cycle Support

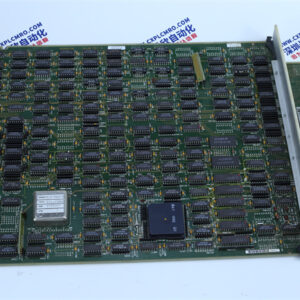

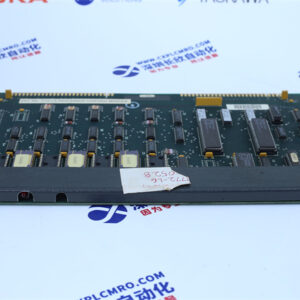

Installing the ALSTOM MVAX31S1DE0754 involves sliding it into a designated slot in a T3000 I/O rack (e.g., MVRA) and connecting field wires to removable terminal blocks. Jumper settings determine whether internal wetting voltage is enabled per channel bank—a key step during commissioning to match field device requirements. The module is auto-detected by the T3000 controller, and channel tags are assigned in the engineering tool without manual addressing.

Maintenance is simplified by front-panel LEDs indicating group-level status (OK/FAULT), while detailed diagnostics appear in the T3000 HMI. Failed units can be replaced in minutes with no system power-down in non-redundant setups, or hot-swapped in redundant configurations. As legacy Alstom hardware, genuine ALSTOM MVAX31S1DE0754 modules are now sourced through certified reconditioning partners who perform full functional validation, firmware verification, and 48-hour burn-in testing to OEM standards. Each unit includes a test certificate and traceable serial number—critical for audit compliance in regulated power sectors.

Contact us for a customized solution—whether you’re maintaining an operational T3000 system, executing a phased control modernization, or securing long-term spares for turbine and boiler protection circuits. In power generation, every contact counts. And with the ALSTOM MVAX31S1DE0754. you can count on it.