💡 Product Overview

💡 Product Overview

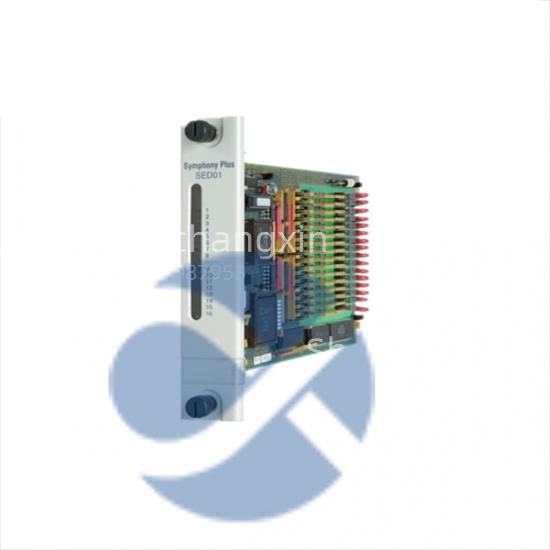

The ABB SPSED01 is a specialized Sequence of Events (SOE) digital input module that serves as a critical component in industrial automation systems requiring precise event chronology. This module belongs to ABB’s S800 I/O family and is designed to integrate seamlessly with Symphony Plus and Bailey INFI 90 distributed control systems (DCS). The primary function of the SPSED01 is to monitor digital field inputs—such as switch status changes, sensor trips, or relay activations—and assign millisecond-precise timestamps to each event. This timestamping capability is crucial for root cause analysis when investigating system faults or process upsets, as it allows engineers to reconstruct the exact sequence of events leading to an incident. The ABB SPSED01 operates with exceptional reliability in harsh industrial environments, featuring robust electrical isolation and surge protection to ensure signal integrity even in electrically noisy conditions. Its ability to maintain an independent event buffer means that data is preserved during communication interruptions, providing an uninterrupted audit trail for compliance and diagnostic purposes .

⚙️ Main Features and Advantages

Millisecond-Precision Event Recording sets the SPSED01 apart from standard digital input modules. With ±1 ms timestamp accuracy across all 16 channels, this module enables engineers to determine the exact sequence of operational events during system disturbances. This precision is critical in complex industrial processes where understanding the order of equipment operations—such as which breaker tripped first during a power grid fault—can reveal the root cause of system failures and help prevent future occurrences .

Robust Design for Harsh Environments ensures reliable operation in demanding industrial settings. The module features 500V AC isolation between channels and surge protection, effectively rejecting electrical noise and transient voltages that could compromise data integrity. With an operating temperature range of -40°C to +70°C, the SPSED01 performs consistently in environments ranging from cold utility substations to hot process areas, maintaining its specified accuracy across this wide range .

Autonomous Operation with Event Buffering provides data protection during system disruptions. Unlike standard input modules that rely on continuous communication with controllers, the SPSED01 maintains an independent buffer that stores thousands of timestamped events. This means that even if communication with the main controller is temporarily lost during a network disturbance or controller maintenance, the module continues recording events without data loss, ensuring a complete historical record for post-event analysis .

Seamless System Integration simplifies engineering and reduces implementation time. The SPSED01 communicates via ModuleBus protocol with AC 800M controllers and integrates natively with ABB’s 800xA Distributed Control System (DCS). This compatibility allows for centralized configuration, monitoring, and event analysis across the entire automation system. The module can be installed alongside other S800 I/O modules on the same rack, optimizing cabinet space and reducing wiring complexity .

🏭 Application Fields

The ABB SPSED01 finds essential application in industries where understanding event sequences is critical for safety, reliability, and regulatory compliance. In power generation and distribution, it timestamp records breaker operations, relay activations, and protection sequences in substations and power plants, providing crucial data for post-fault analysis and compliance with NERC CIP standards .

In oil and gas facilities, the module monitors emergency shutdown systems, valve position changes, and safety interlocks, creating detailed audit trails for incident investigation and regulatory reporting. For chemical and pharmaceutical plants, the SPSED01 helps meet FDA 21 CFR Part 11 electronic record requirements by providing accurate sequence records for batch processes and safety system operations .

The module also serves water and wastewater treatment facilities by recording pump start/stop sequences and valve operations for operational analysis, and supports manufacturing automation where precise event sequencing is needed for production quality analysis and equipment diagnostics .

🔍 Selection and Installation Guidance

When selecting the ABB SPSED01. verify compatibility with your existing ABB control platform—it’s designed for S800 I/O systems working with AC 800M controllers and Symphony Plus DCS. Consider your channel requirements; with 16 inputs per module, determine how many modules are needed to monitor all critical points in your process. For applications requiring synchronized timing across multiple modules or locations, plan for integration with ABB’s IMSET01 time synchronization units to maintain system-wide clock synchronization .

Install the SPSED01 on standard DIN rails within S800 I/O racks, following ABB’s spacing recommendations for proper ventilation. Ensure proper grounding and use shielded cables for signal wiring to maximize noise immunity. During configuration, utilize ABB’s engineering tools to set appropriate filter times and debounce settings based on your application needs, and verify the time synchronization source to maintain timestamp accuracy across the system .

⚠️ Frequently Asked Questions (FAQ)

Q: How does the SPSED01 differ from a standard digital input module?

A: The key difference lies in timestamp precision. While standard DI modules detect state changes, the SPSED01 adds millisecond-accurate timestamps to each event, enabling precise sequencing crucial for fault analysis. It also features independent event buffering to prevent data loss during communications interruptions .

Q: Can the SPSED01 operate in high-electrical-noise environments?

A: Yes, the module is specifically designed for harsh industrial environments. It features 500V AC channel-to-channel isolation and surge protection, making it suitable for installation in electrically noisy areas like switchgear rooms or near heavy machinery .

Q: What is the maximum number of SPSED01 modules that can be used in a system?

A: In a standard S800 I/O configuration, multiple SPSED01 modules can be deployed on the same rack alongside other I/O modules. The specific limit depends on the controller and rack configuration, but systems typically support expansion to monitor hundreds of points across multiple modules .

🔄 Related Products

ABB IMSET01: Time synchronization unit that provides precise clock signals to multiple SPSED01 modules for system-wide event correlation .

ABB DI810: Standard digital input module for applications not requiring millisecond timestamping, often used alongside SPSED01 for non-critical points .

ABB INSEM11: Sequence of Events master module that can work with SPSED01 modules in larger configurations .

AC 800M: ABB’s controller family that communicates with SPSED01 modules via ModuleBus protocol .

S800 I/O Baseplate: Provides mounting and communication backbone for SPSED01 modules in S800 systems