469-P5-HI-A20-E

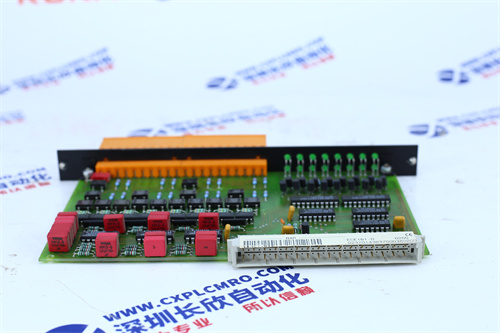

Allen-Bradley 469-P5-HI-A20-E Motor Protection Relay Module

Product Description

The 469-P5-HI-A20-E is an advanced motor protection relay module from Allen-Bradley, designed to monitor, protect, and control medium to large AC motors in industrial applications. As part of Allen-Bradley’s PowerFlex and CenterLine motor control systems, it combines comprehensive protection features with precise control capabilities, ensuring motors operate within safe parameters while optimizing performance. This module is widely used in industries such as manufacturing (conveyor and pump motors), oil and gas (compressor motors), and water treatment (aerator and blower motors), where motor downtime can lead to significant production losses.

In a manufacturing plant, the 469-P5-HI-A20-E continuously monitors a conveyor motor’s current, voltage, temperature, and speed. It detects abnormal conditions such as overloads, phase imbalances, ground faults, and bearing overheating, triggering protective actions (e.g., tripping the motor contactor) to prevent damage. It also enables remote control via communication networks, allowing operators to start/stop the motor or adjust its operating parameters from a central SCADA system. In oil and gas compressor stations, it protects motors from voltage sags and surges common in remote locations, ensuring uninterrupted operation of critical compression systems.

The module features a high-resolution display and intuitive user interface for local configuration and monitoring, with advanced communication capabilities for integration into industrial networks (EtherNet/IP, DeviceNet). It supports customizable protection settings to match specific motor types (induction, synchronous) and application requirements, enhancing flexibility. Built-in energy monitoring functions track power consumption, power factor, and efficiency, aiding in energy management and predictive maintenance. Its rugged design withstands harsh industrial environments, including wide temperature ranges and electromagnetic interference (EMI), ensuring reliable operation in motor control centers and switchgear.