3502E

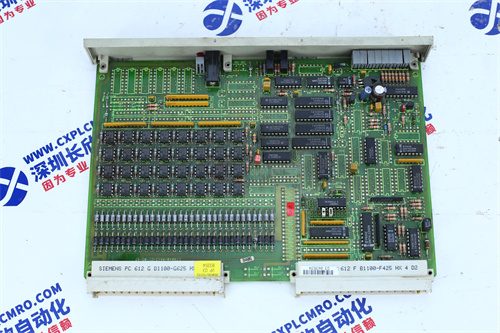

Bently Nevada 3502E Vibration Monitor Module (Machinery Protection System Transducer Interface Unit)

Product Description

The 3502E is a high-performance vibration monitor module developed by Bently Nevada (a Siemens company) for machinery protection systems, designed to continuously measure and analyze vibration levels in rotating equipment such as turbines, compressors, and pumps. Its core function is to process signals from accelerometers, velocity transducers, or proximity probes, detect abnormal vibration patterns (e.g., imbalance, misalignment, bearing wear), and trigger alarms or shutdowns to prevent catastrophic failures. It is widely used in power generation, oil & gas, and petrochemical industries—for example, monitoring the vibration of a gas turbine’s rotor to ensure peak-to-peak displacement remains within 50μm, avoiding costly unplanned outages (average turbine downtime costs $500,000+ per day).

Featuring 4 independent monitoring channels, the module can simultaneously track vibration parameters (acceleration, velocity, displacement) from multiple measurement points on a single machine. Each channel supports a range of transducer types: proximity probes (for shaft relative vibration, -200mV to +200mV DC), velocity transducers (for casing vibration, 0-50mm/s RMS), and accelerometers (for high-frequency vibration, 0-10g peak). With a 24-bit ADC (analog-to-digital converter) and a sampling rate of 51.2kHz per channel, it captures high-resolution data, enabling detailed frequency analysis (up to 25kHz) to identify specific fault frequencies (e.g., 2× rotational speed indicating misalignment).