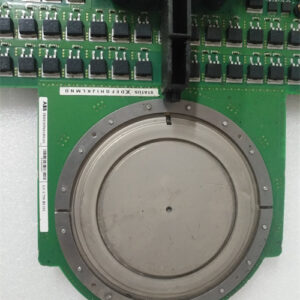

3500/40M 140734-01

Product Name

Bently Nevada 3500/40M 140734-01 Machinery Vibration Monitoring Module (As a core vibration analysis component in Bently Nevada’s 3500 monitoring system, featuring multi-channel data acquisition and real-time fault diagnostics, it serves as the “condition monitoring sentinel” for rotating equipment in industrial plants)

Product Description

The 3500/40M 140734-01 is a high-performance machinery vibration monitoring module developed by Bently Nevada, specifically designed for integration into the 3500 machinery protection and condition monitoring system. It is widely deployed in power generation, oil & gas, and petrochemical industries to monitor critical rotating equipment such as turbines, compressors, and pumps. In a steam turbine installation, this module continuously collects vibration data from up to 4 proximity probes (measuring shaft displacement) and 4 accelerometers (monitoring bearing housing vibration), processing the signals to detect anomalies like unbalance, misalignment, or bearing wear, and triggering alarms or shutdowns before catastrophic failures occur.

Each of the 8 input channels (configurable as 4+4 or 8 single-ended) supports a range of vibration sensors, including Bently Nevada’s 3300 series proximity systems (for shaft relative vibration) and 3500 series accelerometers (for absolute vibration). The module processes signals at a 2560Hz sampling rate, calculating key parameters such as peak-to-peak amplitude, RMS, and phase, which are transmitted to the 3500 frame controller for further analysis. Advanced features include programmable alarm setpoints (alert and danger levels), frequency filtering (1Hz to 10kHz), and trend logging, enabling predictive maintenance strategies.