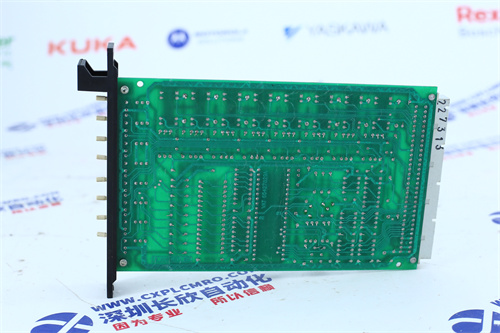

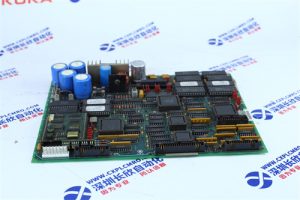

3500/25 125792-01

3500/25 125792-01 Machinery Protection System Input Module

Product Description

The 3500/25 125792-01 is a critical input module designed for the Bently Nevada 3500 machinery protection system, specialized in acquiring and processing vibration and position signals from rotating machinery such as turbines, compressors, motors, and pumps. It serves as a key component in industrial monitoring systems, enabling real-time detection of mechanical faults (e.g., imbalance, misalignment, bearing wear) to prevent catastrophic failures and ensure operational safety.

In a power plant, for example, this module continuously collects vibration data from steam turbine bearings via accelerometers and proximity probes. It converts these raw signals into meaningful measurements (like velocity, displacement, and acceleration) and transmits them to the 3500 frame controller. If the data exceeds predefined alarm thresholds, the system triggers alerts or shutdown sequences to protect the turbine from damage. In a petrochemical refinery, it monitors centrifugal compressor vibrations, helping maintenance teams schedule predictive repairs and minimize unplanned downtime.

Featuring high-resolution signal processing and rugged construction, the module operates reliably in harsh industrial environments with high temperatures, humidity, and electromagnetic interference. It integrates seamlessly with the 3500 system’s redundant architecture, ensuring data integrity and system availability in critical applications.