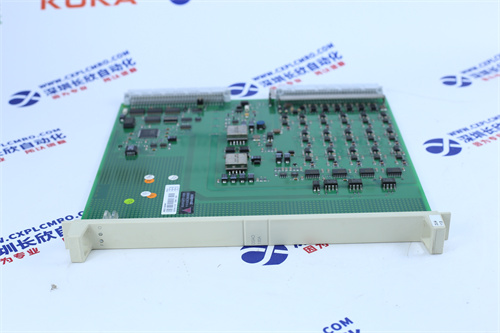

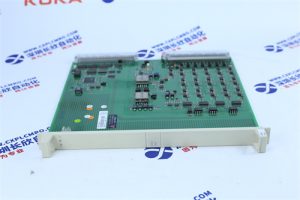

3500/20 125768-01小卡

Product Name

Bently Nevada 3500/20 125768-01 4-Channel Machinery Vibration/Position Input Interface Small Card Module (3500 Monitoring System Dedicated)

(Naming convention explanation for Bently 3500 small card modules:

- “3500/20”: Product family identifier, denoting the “4-Channel Input Module” category in the 3500 ecosystem—distinguished from “3500/42” (vibration monitors) or “3500/92” (communication gateways).

- “125768-01″: Bently’s unique part number for the standard small card variant—”125768” is the base model code; “01” specifies the non-hazardous area version (vs. “02” for ATEX/IECEx certified models).

- “Small Card”: Refers to its compact, plug-in form factor (vs. full-size 3500 modules), designed for dense integration in 3500 rack systems.

- Core positioning: Acts as the “signal conditioning hub” for 3500 systems, accepting raw sensor signals (from proximity probes, accelerometers) and converting them into digitized data for health monitoring and fault detection.)

2. Product Description

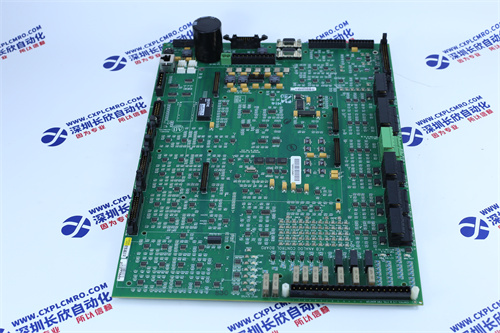

The Bently Nevada 3500/20 125768-01 small card module is a precision-engineered sensor interface component, critical for machinery health monitoring in industries like power generation (turbines), oil & gas (compressors), and manufacturing (pumps/motors). As a compact plug-in module for the 3500 rack system, it addresses signal integrity and multi-sensor integration challenges by:

2.1 Multi-Sensor Signal Conditioning

Supports diverse industrial vibration/position sensors, eliminating the need for separate interface modules:

- Proximity Probe Compatibility: Accepts signals from Bently 3300/3500 series proximity probes (e.g., 330180) for measuring shaft position, vibration, and eccentricity—supports probe drive voltage (18V DC) and gap voltage (0–10V DC) monitoring.

- Accelerometer/Velocity Sensor Support: Integrates differential input circuits for IEPE (Integrated Electronics PiezoElectric) accelerometers and velocity transducers, with configurable gain (1–1000x) to match sensor sensitivity (e.g., 100mV/g accelerometers).

- Signal Filtering: Built-in low-pass/high-pass filters (configurable cutoff frequencies: 0.1Hz–1kHz) to suppress noise from electrical interference or mechanical harmonics, ensuring accurate data for vibration analysis.

2.2 4-Channel Parallel Processing

Enables simultaneous monitoring of multiple machinery components:

- 4 independent, isolated channels (each with dedicated signal conditioning circuitry) to avoid cross-talk between sensors—ideal for monitoring multi-shaft equipment (e.g., gas turbines with high-pressure/low-pressure shafts).

- Each channel supports real-time signal digitization (16-bit ADC, 1kHz sampling rate) and transmits data to the 3500 system’s mainframe for health calculations