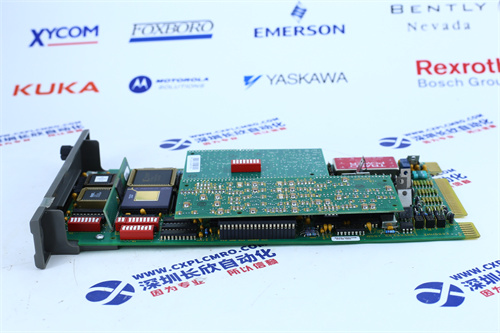

PDD500A101

The product is named the PDD500A101 module, which is manufactured by ABB. It is a highly reliable and efficient module designed for industrial automation systems.

2. Product Description

2.1 General Function

The PDD500A101 module serves as a digital input module in industrial control systems. It is responsible for receiving digital signals from various field devices, such as sensors, switches, and pushbuttons, and converting them into a format that can be processed by the control system. The module then transmits these processed signals to the central processing unit (CPU) of the control system for further analysis and decision – making. This enables the control system to monitor the status of the industrial process and take appropriate actions based on the received signals.

2.2 Applications

- Industrial Automation in Manufacturing: In manufacturing plants, the PDD500A101 module is widely used in automated production lines. It can interface with proximity sensors to detect the position of parts on a conveyor belt. When a part is detected at a specific location, the module sends a signal to the control system, which can then trigger a robotic arm to pick up and assemble the part. It also works with limit switches to control the movement of machinery, ensuring that equipment operates within safe limits. For example, in a car manufacturing plant, the module can monitor the position of car bodies as they move along the assembly line, and control the operation of various assembly stations.

- Power Generation and Distribution: In power plants, this module plays a crucial role. It can receive signals from sensors that monitor the status of generators, transformers, and circuit breakers. For instance, it can detect if a circuit breaker has tripped due to an overload or a short – circuit. In a thermal power plant, it can also monitor the status of valves and pumps in the boiler and turbine systems. In power distribution networks, the PDD500A101 module can be used to monitor the status of switches and relays in substations, ensuring the reliable distribution of electricity.

- Process Control in Chemical and Petrochemical Industries: In chemical and petrochemical plants, the module is used to control chemical reactions and processing units. It can receive signals from level sensors in storage tanks to monitor the level of chemicals. When the level reaches a certain threshold, the module can send a signal to the control system to start or stop a pump that transfers the chemical. It also works with pressure sensors in reactors to ensure that the pressure remains within the safe operating range. For example, in a polymerization process, the module can monitor the status of various sensors and control the addition of catalysts and monomers to ensure the production of high – quality polymers.