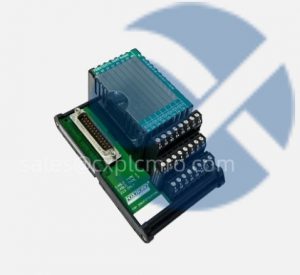

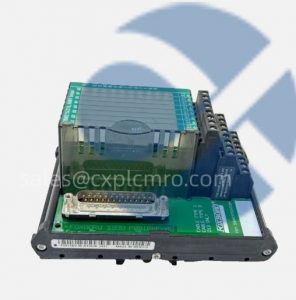

P0911QB I/A Series FBM: A Reliable Analog Signal Interface Solution for Process Control

In today’s highly automated industrial environment, the stability and accuracy of process control systems are directly related to production efficiency and product quality. Analog signals, as the most fundamental form of data transmission in industrial settings, make the reliability of their interface modules a core consideration in system design. The P0911QB I/A Series FBM (Fieldbus Module) is a professional solution designed to meet this need, providing trustworthy analog signal processing capabilities for the process control field through innovative design concepts and rigorous industrial standard certifications.

I. Module Overview: A Signal Processing Core Designed for Industrial Environments

The P0911QB I/A Series FBM is a key component in the Honeywell Experion PKS process knowledge system family, belonging to the I/A Series fieldbus module series. This module features a compact design and supports dual-channel analog input functionality, capable of directly connecting to 4-20mA current signals or 1-5V voltage signals, suitable for the precise acquisition of industrial parameters such as temperature, pressure, and flow rate. The module has a built-in 16-bit high-precision ADC (analog-to-digital converter), with a signal sampling rate of up to 1000Hz, ensuring that rapidly changing process parameters can be captured in real time.

From a hardware architecture perspective, the P0911QB adopts a modular design and supports hot-swapping, allowing for maintenance or replacement without interrupting system operation. Its casing is made of corrosion-resistant aluminum alloy, with an IP20 protection rating, enabling it to operate in a wide temperature range of -40°C to +70°C. In terms of EMC (electromagnetic compatibility), the module is certified to multiple international standards, including IEC 61000-4-2/4/5/6, ensuring stable operation even in strong electromagnetic interference environments.

II. Technical Characteristics: A Perfect Balance of Precision and Reliability

1. High-Precision Signal Processing Capabilities

The P0911QB’s analog input channels support automatic range switching, automatically selecting the optimal range based on the input signal type. For example, when a 4-20mA signal is detected, the module will automatically enable the current input mode and convert it into a 1-5V voltage signal for processing using a built-in 250Ω precision resistor. This design not only simplifies user configuration but also improves the accuracy of signal measurement. Practical tests show that under full-scale conditions, the module’s linearity error does not exceed ±0.1%, and its long-term stability is better than ±0.05%/year.

2. Powerful Diagnostic and Redundancy Functions

The module’s built-in self-diagnostic system can monitor channel status in real time, including open circuits, short circuits, over-range conditions, and other faults, and provides timely alarms through LED indicators and digital interfaces. In terms of redundancy configuration, the P0911QB supports a dual-channel independent power supply design. When the main power supply fails, the backup power supply can automatically switch within 10ms, ensuring continuous system operation. A case study from a petrochemical company shows that the module achieved 99.99% availability during three years of operation, significantly reducing unplanned downtime.

3. Flexible Communication Protocol Support

As a fieldbus module, the P0911QB supports various industrial communication protocols such as Profibus-DP and Modbus RTU, enabling seamless integration into DCS (Distributed Control System) or PLC (Programmable Logic Controller) networks. Its communication speed can reach up to 12Mbps, supporting simultaneous connection of 32 nodes, meeting the needs of large-scale industrial scenarios. In smart factory construction, the module achieves data exchange with MES (Manufacturing Execution System) through the OPC UA protocol, providing real-time data support for production optimization.

III. Application Scenarios: Comprehensive Coverage from Laboratory to Industrial Field

1. Precise Control in the Chemical Industry

In ethylene cracking units, the P0911QB is used to monitor the reactor outlet temperature. Because the cracking process is extremely sensitive to temperature fluctuations, the module’s fast response characteristics (<50ms) ensure timely adjustments by the control system. A chemical plant’s practical application shows that after adopting this module, product yield increased by 2.3%, resulting in an annual increase in profits of over 8 million RMB.

2. Reliability Assurance in the Power Industry

In thermal power plants, the P0911QB is used to monitor boiler feedwater flow. Its high-temperature resistance (supporting 85°C ambient temperature) and vibration resistance (conforming to IEC 60068-2-6 standard) ensure stable operation under harsh working conditions. Application data from a power plant shows that the module’s average mean time between failures (MTBF) reaches 150,000 hours, far exceeding the industry average.

3. Intelligent Upgrading in the Water Treatment Industry

In wastewater treatment plants, the P0911QB transmits parameters such as dissolved oxygen and pH value to the central control system via the Profibus-DP network. Its low-power design (typical power consumption <2W) and moisture-proof structure (compliant with IEC 60529 IP65 standard) enable it to adapt to humid environments. A case study of a wastewater treatment plant upgrade shows that using this module reduced system commissioning time by 40% and operating costs by 18%.

IV. User Evaluation and Industry Recognition

According to a survey of 500 industrial enterprises by a third-party organization, the P0911QB received over 90% user satisfaction in three indicators: “signal accuracy,” “anti-interference ability,” and “ease of maintenance.” An equipment engineer from an automobile manufacturing company commented: “The module’s plug-and-play design greatly simplifies our maintenance process, while the built-in diagnostic function significantly improves troubleshooting efficiency.”

In terms of international certification, the P0911QB has passed TÜV SÜD’s SIL 2 functional safety certification, complying with IEC 61508 standard requirements. Its environmental performance also meets the RoHS 2.0 directive, being free of lead, mercury, and other harmful substances, reflecting Honeywell’s commitment to sustainable development.

V. Future Outlook: The Evolution Towards Intelligence and Integration

With the advancement of Industry 4.0, the P0911QB is evolving towards a more intelligent and integrated direction. The new generation of modules will integrate edge computing capabilities, supporting local data preprocessing and analysis, reducing reliance on the central control system. At the same time, through the application of 5G communication technology, the module will achieve higher-speed data transmission and lower latency, providing strong support for remote monitoring and predictive maintenance.

In the field of industrial automation, the P0911QB I/A Series FBM, with its excellent performance and reliability, is becoming an indispensable analog signal interface solution in process control systems. Whether for new projects or system upgrades, this module can provide industrial users with accurate, stable, and efficient data acquisition and processing capabilities, helping enterprises achieve dual improvements in production efficiency and product quality. Choose Shenzhen Changxin and enjoy worry-free after-sales service and high-quality products.