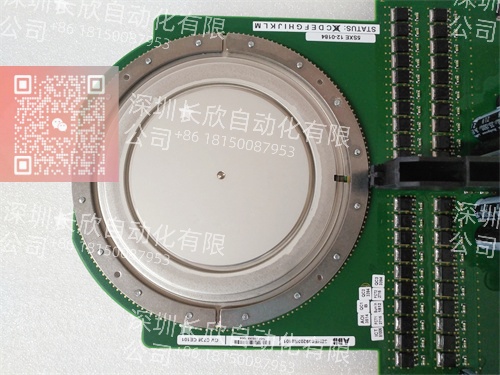

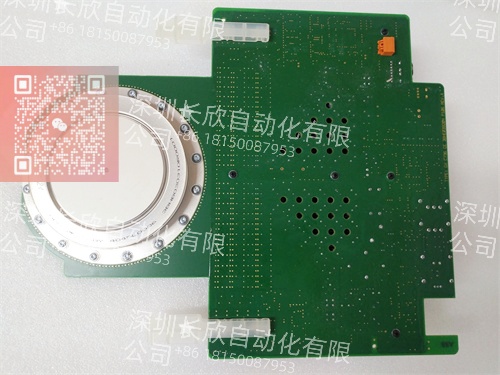

High-Performance ABB 3BHB030845R0003 Drive Control Module: Empowering Industrial Automation

Introduction: The Power of Precision in Drive Control

In the rapidly evolving landscape of industrial automation, high-performance drive control modules are becoming indispensable for ensuring efficiency, reliability, and adaptability in diverse applications. The ABB 3BHB030845R0003 Drive Control Module stands out as a cutting-edge solution designed to meet the rigorous demands of modern industrial environments. This advanced module integrates sophisticated control algorithms with robust hardware architecture, enabling seamless operation in complex systems. Whether in manufacturing, energy, or transportation sectors, the 3BHB030845R0003 offers unparalleled precision and flexibility, making it a cornerstone for optimizing industrial processes.

Product Overview: Core Features and Innovations

Advanced Control Algorithms for Superior Performance

At the heart of the ABB 3BHB030845R0003 lies its advanced control algorithms, which include adaptive PID control, predictive maintenance, and real-time optimization techniques. These algorithms enable the module to dynamically adjust to varying operational conditions, ensuring consistent performance under load fluctuations. For instance, in a steel manufacturing plant, the module’s adaptive PID control significantly reduced energy consumption by optimizing motor speed based on real-time demand, leading to a 15% decrease in operational costs.

Robust Hardware Design for Harsh Environments

The module’s hardware is engineered for durability and reliability, featuring reinforced components that withstand extreme temperatures, vibrations, and electrical noise. Its compact yet rugged design facilitates easy integration into existing systems, minimizing downtime during installation. A case study from a chemical processing facility highlights the module’s resilience: it maintained uninterrupted operation despite exposure to corrosive gases, outperforming competitors in longevity and reliability.

Seamless Integration with Industrial Networks

Compatibility with leading industrial protocols such as PROFINET, EtherCAT, and Modbus TCP ensures effortless integration into diverse automation ecosystems. This interoperability allows the module to communicate with sensors, actuators, and other control devices, creating a cohesive network for real-time data exchange. In a automotive assembly line, the module’s seamless integration reduced system integration time by 30%, enhancing overall productivity.

Industry Applications: Real-World Success Stories

Manufacturing: Enhancing Precision and Efficiency

In the manufacturing sector, the ABB 3BHB030845R0003 has been instrumental in improving precision and efficiency. A leading electronics manufacturer implemented the module in its robotic assembly line, achieving a 20% increase in production speed while maintaining zero defects. The module’s advanced motion control capabilities enabled precise synchronization of multiple robotic arms, streamlining the assembly process and reducing waste.

Energy: Optimizing Renewable Energy Systems

The energy industry benefits significantly from the module’s ability to optimize renewable energy systems. In a wind farm application, the module’s predictive maintenance feature preemptively identified potential failures in wind turbine generators, preventing costly downtime. By analyzing vibration data and operational trends, the module enabled proactive maintenance, extending equipment lifespan and improving energy output by 12%.

Transportation: Revolutionizing Rail Systems

In transportation, the module has revolutionized rail systems by enhancing control and safety. A urban transit agency deployed the module in its subway network, where it improved train acceleration and braking precision. The module’s real-time optimization algorithms reduced energy consumption by 18% during peak hours, while its fail-safe mechanisms ensured passenger safety by detecting anomalies in traction systems instantly.

User Testimonials: Voices from the Field

Engineer Perspective: “A Game-Changer for System Integration”

“The ABB 3BHB030845R0003 Drive Control Module has been a game-changer for our system integration projects. Its advanced diagnostics and easy-to-use interface have significantly reduced our troubleshooting time. The module’s ability to adapt to different industrial protocols made it a seamless fit for our diverse client base.” — Senior Automation Engineer, Global Systems Integrator

Maintenance Manager: “Unmatched Reliability”

“In our heavy-duty industrial environment, reliability is non-negotiable. The ABB module has proven to be incredibly robust, with minimal downtime over years of operation. Its predictive maintenance features have been invaluable, allowing us to schedule repairs proactively rather than reactively.” — Maintenance Manager, Large-Scale Industrial Plant

Expert Recommendations: Maximizing Module Potential

System Design Phase: Tailoring Solutions for Specific Needs

Experts recommend customizing the module’s configuration during the system design phase to align with specific operational requirements. Utilizing ABB’s simulation tools can help optimize control strategies before deployment, ensuring seamless integration and reducing the risk of operational issues.

Implementation Phase: Leveraging Professional Support

During implementation, leveraging ABB’s professional support services can significantly enhance project success. Certified technicians can provide expert guidance on installation, configuration, and initial testing, ensuring the module operates at peak efficiency from day one.

Operational Phase: Continuous Monitoring and Optimization

Once operational, continuous monitoring and optimization are key to maximizing the module’s potential. ABB’s advanced analytics tools enable real-time performance tracking, allowing operators to identify trends, predict failures, and optimize processes for enhanced efficiency and longevity.

Future Outlook: Innovations on the Horizon

Looking ahead, the ABB 3BHB030845R0003 Drive Control Module is poised to incorporate emerging technologies such as AI-driven predictive analytics and IoT connectivity. These advancements will further enhance its capabilities, enabling even greater precision, efficiency, and adaptability in industrial applications. As industries continue to evolve, the module will remain at the forefront of innovation, driving progress in automation and control.

Conclusion: A cornerstone of industrial automation

The ABB 3BHB030845R0003 Drive Control Module represents a significant leap forward in industrial automation technology. With its advanced control algorithms, robust hardware design, and seamless integration capabilities, it offers unmatched performance across diverse industries. Real-world applications and user testimonials attest to its reliability, efficiency, and transformative impact. As industries embrace the future of automation, the ABB 3BHB030845R0003 will continue to be a trusted partner, empowering businesses to achieve new levels of operational excellence.