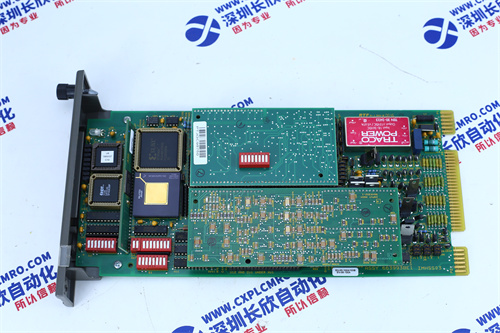

DSDX404

The product is named the DSDX404 module, which is manufactured by ABB. It is a significant component commonly applied in industrial automation and control systems, playing a vital role in ensuring the smooth operation of various industrial processes.

2. Product Description

2.1 General Function

The DSDX404 module functions as a digital input/output module. Its core role is to act as an interface between field devices and the central control system in industrial setups. On the input side, it receives digital signals from various sources such as proximity sensors, limit switches, and pushbuttons. These signals carry information about the status of equipment, the position of parts, or operator commands. The module then processes these input signals, converting them into a format that can be easily understood by the control system’s central processing unit (CPU). On the output side, it sends digital control signals to actuators like relays, solenoids, and motors, enabling the control system to manipulate industrial equipment and adjust the operation of the production process.

2.2 Applications

- Manufacturing Industry: In manufacturing plants, the DSDX404 module is widely used in automated production lines. For example, in an automotive assembly line, it can receive input signals from sensors that detect the presence and position of car bodies on conveyor belts. Based on these signals, it can send output commands to robotic arms to initiate the assembly of components such as engines, doors, and seats. It also monitors the operation of various machines, using input signals from sensors to detect issues like machine malfunctions or tool wear, and then sends appropriate output signals to stop the machine or trigger an alarm for maintenance.

- Power Generation and Distribution: In power plants, the DSDX404 module is crucial for monitoring and controlling power – generating equipment. It can receive input signals from sensors that measure parameters such as the temperature, pressure, and rotational speed of turbines. Using this information, it sends output signals to control valves, pumps, and other auxiliary equipment to optimize power generation. In power distribution networks, it monitors the status of circuit breakers, switches, and transformers through input signals and can send output commands to remotely operate these devices, ensuring the reliable distribution of electricity.