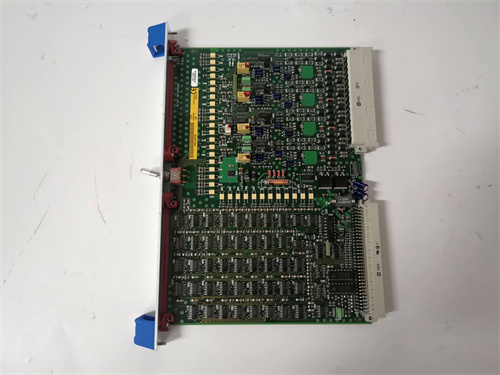

ABB 940181103 OCAH | Industrial Fiber Optic Communication Interface

In the rapidly evolving landscape of industrial automation, reliable and high-speed communication interfaces are indispensable for ensuring seamless data transmission and system integration. The ABB 940181103 OCAH industrial fiber optic communication interface stands out as a robust solution designed to meet the demanding requirements of modern industrial environments. This article delves into the technical specifications, application scenarios, and real-world benefits of the OCAH module, providing valuable insights for industry professionals.

Introduction to ABB OCAH 940181103

Core Features and Design Philosophy

The ABB OCAH 940181103 is a cutting-edge fiber optic communication interface tailored for industrial automation systems. Its design prioritizes durability, efficiency, and adaptability, making it ideal for harsh industrial settings. Key features include:

High-Speed Data Transmission: Utilizing fiber optic technology, the OCAH module ensures rapid and reliable data transfer, minimizing latency and enhancing system responsiveness.

Robust Construction: Built to withstand extreme temperatures, vibrations, and electromagnetic interference, the module guarantees uninterrupted operation in challenging environments.

Modular Flexibility: The interface supports seamless integration with various industrial devices, enabling scalable and customizable automation solutions.

Real-World Application: Power Generation Sector

In a recent project at a large-scale power plant in Germany, the OCAH module was deployed to enhance communication between distributed control systems (DCS) and field devices. The plant’s existing copper-based network faced issues with signal degradation over long distances. By transitioning to fiber optic technology, the OCAH module eliminated these challenges, ensuring stable data transmission and significantly reducing downtime due to communication failures.

Technical Specifications and Performance

Communication Protocols and Compatibility

The OCAH 940181103 supports industry-standard protocols such as PROFINET and Modbus TCP/IP, facilitating effortless integration with diverse industrial equipment. Its compatibility with ABB’s automation suite ensures smooth interoperability within existing infrastructure.

Environmental Resilience

Designed for industrial-grade applications, the module operates efficiently across a wide temperature range (-40°C to +85°C). Its IP-rated enclosure provides protection against dust and moisture, making it suitable for deployment in outdoor and hazardous environments.

User Testimonials: Oil and Gas Industry

A leading oil refining company in Norway implemented the OCAH module in its offshore drilling operations. The company reported a 30% reduction in communication-related downtime after switching to fiber optic interfaces. Maintenance personnel highlighted the module’s ease of installation and minimal troubleshooting requirements, emphasizing its role in enhancing operational efficiency.

Installation and Configuration Best Practices

Step-by-Step Setup Guide

Hardware Installation: Begin by securely mounting the OCAH module in a control cabinet. Ensure proper alignment of fiber optic connectors to prevent signal loss.

Network Configuration: Use ABB’s dedicated software tools to configure network parameters, including IP addresses and communication protocols. The intuitive interface simplifies the setup process, even for non-specialist technicians.

Testing and Validation: Conduct comprehensive tests to verify data integrity and transmission speeds. Real-time monitoring tools provided by ABB enable immediate issue identification and resolution.

Case Study: Chemical Processing Plant

A chemical plant in the Netherlands faced challenges with its legacy communication system, which struggled to handle high-speed data from advanced sensors. After installing the OCAH module, the plant achieved a seamless transition to fiber optic communication. The module’s plug-and-play design reduced installation time by 50%, allowing the plant to resume full operations swiftly.

Advantages Over Traditional Communication Methods

Enhanced Data Integrity

Fiber optic technology offers superior immunity to electromagnetic interference compared to copper-based systems. This ensures accurate data transmission, critical for precision-driven industries such as pharmaceuticals and semiconductor manufacturing.

Long-Distance Communication Capabilities

The OCAH module supports extended transmission distances without signal loss, making it ideal for large-scale industrial facilities. In a steel mill application in Sweden, the module enabled reliable communication across a sprawling production site, eliminating the need for costly signal boosters.

Cost-Effectiveness and ROI

While initial investment in fiber optic infrastructure may be higher, long-term cost savings are substantial. Reduced maintenance, lower energy consumption, and enhanced system reliability contribute to a favorable return on investment. Industry experts estimate a payback period of less than two years for most applications.

Future Trends and Expert Insights

Industry 4.0 Integration

As Industry 4.0 technologies gain traction, the demand for high-speed, reliable communication interfaces like the OCAH module is poised to grow. Experts predict widespread adoption in smart factories, where real-time data analytics and machine learning algorithms rely on robust communication networks.

Maintenance and Longevity Tips

Regularly inspect fiber optic connectors for dust or damage. Use ABB’s diagnostic tools for proactive maintenance. Industry professionals recommend scheduled firmware updates to ensure compatibility with evolving technologies.

Conclusion

The ABB OCAH 940181103 industrial fiber optic communication interface represents a significant advancement in industrial automation technology. Its combination of high-speed data transmission, environmental resilience, and ease of installation makes it a preferred choice for industries ranging from power generation to chemical processing. Real-world applications demonstrate its ability to enhance operational efficiency, reduce downtime, and deliver substantial cost savings. As industrial environments continue to evolve, the OCAH module is well-positioned to meet the growing demands for reliable and scalable communication solutions.