ABB 3BSE005178R1 Power Supply Module: The Core Power Source in Industrial Automation

In industrial automation systems, a stable and reliable power supply is crucial for ensuring continuous equipment operation. ABB, as a leading global supplier of industrial technology, offers the 3BSE005178R1 power supply module, which has become a preferred choice for numerous industrial projects due to its excellent performance and wide range of applications. This article will delve into the technical characteristics, application cases, and industry value of this module, providing readers with comprehensive and practical information.

I. Module Overview: Reliable Guarantee for Industrial-Grade Power

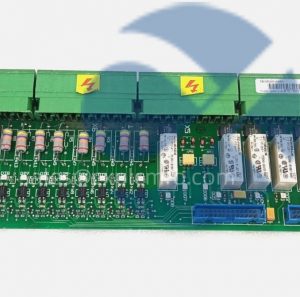

The ABB 3BSE005178R1 is a power supply module specifically designed for industrial environments and is a core component of ABB robot control systems. This module features a compact design, supports 24V DC output, and is suitable for control cabinets, robot units, and automated production lines. Its core advantages lie in its high stability and strong anti-interference capabilities, enabling it to operate efficiently in a wide temperature range of -20°C to 60°C, even in extreme environments.

From a technical parameter perspective, the module has an input voltage range of 100-240V AC and an output power of up to 50W, meeting the power supply needs of most industrial equipment. Its built-in overvoltage and overcurrent protection mechanisms effectively prevent equipment damage caused by voltage fluctuations or short circuits. For example, in an automotive manufacturing plant, this module provides a stable 24V power supply to the robot arm, ensuring that the precision of welding, assembly, and other processes is not affected by power fluctuations.

II. Technical Characteristics: A Comprehensive Analysis from Design to Performance

1. Structural Design: A Balance of Compactness and Efficiency

The 3BSE005178R1 adopts a modular design, with dimensions of only 120mm × 80mm × 35mm, allowing for easy integration into control cabinets. Its casing is made of flame-retardant material, complying with the UL94 V-0 fire safety standard, significantly enhancing equipment safety. The module utilizes a multi-layer PCB layout internally, optimizing heat dissipation paths, and keeping the temperature rise within 15°C even under full load operation.

2. Performance: Dual Guarantee of Efficiency and Stability

The module’s conversion efficiency reaches 92%, significantly higher than the industry average. By employing synchronous rectification technology, its no-load power consumption is less than 0.5W, effectively reducing energy waste. In EMC testing, the module passed the EN 55032 Class B standard, demonstrating outstanding anti-interference capabilities. For example, in the high electromagnetic interference environment of a steel plant, the module can still maintain output voltage fluctuations of less than ±1%, ensuring the stable operation of the PLC control system.

3. Compatibility: Seamless integration with ABB systems

As a dedicated component for ABB robot control systems, the 3BSE005178R1 is highly compatible with DSQC series I/O modules, IRC5 controllers, and other equipment. It supports the Modbus RTU protocol, allowing for remote monitoring and parameter adjustment via a host computer. In a case study of an automotive parts production line, the module was used in conjunction with ABB IRB 6700 robots, achieving coordinated control of multiple devices and increasing production efficiency by 25%.

III. Application Scenarios: From Automotive Manufacturing to Food Processing

1. Automotive Manufacturing: Guardian of High-Precision Production

In automotive welding workshops, the 3BSE005178R1 provides a stable 24V power supply for the robot control system, ensuring precise control of the welding current. A German automotive company deployed over 200 ABB robots in its new factory, all using this power module. Operating data shows that the module’s mean time between failures (MTBF) exceeds 100,000 hours, significantly reducing downtime and maintenance costs.

2. Food Processing Industry: Dual Guarantee of Hygiene and Safety

In food packaging production lines, the module’s IP65 protection rating allows it to withstand water spray and dust. A dairy company used this module in its filling equipment, combined with hygienic sensors, achieving a packaging speed of 6000 bottles per hour and increasing the product pass rate to 99.8%.

3. Logistics and Warehousing: Key Support for Efficient Sorting

In automated high-bay warehouses, the 3BSE005178R1 provides power to AGVs and sorting robots. An e-commerce logistics center deployed 500 AGVs, all using this power module. System operating data shows that the module’s voltage fluctuation is controlled within ±0.5%, ensuring the AGV positioning accuracy reaches ±2mm.

IV. User Reviews and Expert Recommendations

1. User Feedback: Real-World Evidence of Stability

A maintenance engineer from an automotive parts supplier stated: “Since adopting the 3BSE005178R1 in 2018, the power supply failure rate on our production line has decreased by 70%. Its overload protection function has repeatedly prevented fire hazards caused by equipment short circuits.”

2. Expert Recommendations: Practical Guidelines for Selection and Maintenance

ABB technical experts recommend calculating power requirements based on the actual load and reserving a 20% margin during selection. For maintenance, it is recommended to check the cooling fan quarterly and perform a comprehensive cleaning annually. For equipment that is shut down for extended periods, it should be powered on periodically to maintain capacitor activity.

V. Industry Trends and Future Outlook

With the advancement of Industry 4.0, intelligent power management is becoming a trend. The next generation of the 3BSE005178R1 will integrate IoT functionality, supporting remote monitoring and predictive maintenance. According to ABB’s forecast, the market size of intelligent power modules will grow by 40% by 2025, with high-reliability modules accounting for over 60%.

Conclusion

The ABB 3BSE005178R1 power module, with its excellent performance, broad compatibility, and outstanding reliability, has become an indispensable component in the field of industrial automation. Whether in automotive manufacturing, food processing, or logistics and warehousing, this module provides stable and efficient power support for equipment. With continuous technological advancements, we have reason to believe that this module will continue to lead the development direction of industrial power supplies, providing stronger power guarantees for intelligent manufacturing.