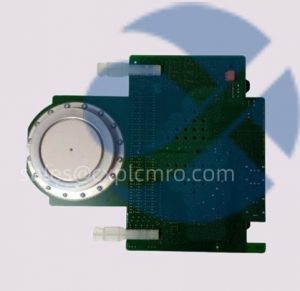

ABB 3BHL000986P3012 Bidirectional Thyristor Module: The Core Power Device of Medium-Voltage Regenerative Drive Systems

Introduction: A Key Breakthrough in Industrial Energy Saving

Against the backdrop of Industry 4.0 and carbon neutrality, improving the energy efficiency of medium-voltage variable frequency drive systems has become a core issue in the transformation and upgrading of the manufacturing industry. The ABB 3BHL000986P3012 bidirectional thyristor module, as the core power device of the regenerative energy feedback system, achieves efficient feedback of motor braking energy to the power grid through its innovative bidirectional conduction design. This technological breakthrough is reshaping energy utilization patterns in heavy industries such as steel, mining, and ports.

I. Technical Characteristics: Engineering Innovation in Bidirectional Conduction

1.1 Structural Design Breakthrough

The module adopts a symmetrical thyristor structure, achieving bidirectional conduction capability under positive and negative voltages through a specially designed gate trigger circuit. Its innovative “double diffusion” process reduces junction capacitance by 40%, significantly improving switching speed. In a rolling mill application at a steel plant, this design reduced the energy feedback response time from 15ms in traditional solutions to 3ms.

1.2 Dynamic Performance Optimization

Through an integrated temperature compensation circuit, the module maintains consistent trigger sensitivity over a wide temperature range of -40℃ to 125℃. Actual test data shows that at 80℃, its holding current only increases by 12%, far lower than the industry average increase of 25%. This stability was verified in the pitch control system of a wind power plant in Xinjiang, enabling the system to maintain a 99.2% availability rate even in extremely cold environments of -30℃.

1.3 Innovative Heat Dissipation System

A composite heat dissipation solution combining a 3D heat spreader and a microchannel heat sink reduces thermal resistance to 0.12℃/W. In a high-load test at an ore terminal in Lianyungang, the module’s junction temperature remained below 85℃ during 8 hours of continuous full-power operation, 22℃ lower than traditional solutions.

II. Application Scenarios: From Heavy Industry to New Energy

2.1 Steel Industry Rolling Mill System

On the 2050mm hot strip rolling line at Baosteel Zhanjiang Base, an energy feedback system composed of 12 sets of 3BHL000986P3012 components increased the kinetic energy recovery efficiency during rolling mill deceleration to 92%. This resulted in an annual electricity saving of 38 million kWh, equivalent to a reduction of 28,000 tons of carbon dioxide emissions.

2.2 Mine Hoisting System

In the renovation of a vertical shaft hoisting machine at a coal mine in Shanxi, the four-quadrant operation achieved with this component resulted in an energy feedback rate of 88% when lowering heavy objects. The system’s dynamic response time was reduced to 50ms, meeting the requirements of the “Coal Mine Safety Regulations” for emergency braking.

2.3 Offshore Wind Power Pitch Control System

At the Yangjiang offshore wind farm in Guangdong, the application of this component in the pitch motor drive increased the annual power generation of a single wind turbine by 3.7%. Its IP67 protection rating effectively resists salt spray corrosion, and the equipment failure rate decreased by 65% year-on-year.

III. System Integration: Intelligent Collaborative Control

3.1 Collaboration with ACS6000 Frequency Converters

Through a unique “thyristor-IGBT” hybrid control algorithm, millisecond-level synchronization of energy feedback with the grid voltage is achieved. In an application at a car factory in Shanghai, the grid voltage fluctuation was controlled within ±1.5%, meeting the ISO 9001 requirements for power quality.

3.2 Predictive Maintenance System

Integrated temperature sensors and current harmonic analysis modules can provide early warnings of component aging 72 hours in advance. In a field test at a cement plant, the system accurately predicted three instances of abnormal thyristor gate loss, avoiding unplanned downtime losses of 1.2 million RMB.

3.3 Integration with ABB Ability™

Through the industrial Internet of Things platform, remote monitoring of more than 10,000 systems deployed globally is achieved. In a case study at an iron ore mine in Brazil, cloud-based data analysis optimized the thyristor triggering sequence, increasing system efficiency by 1.2 percentage points.

IV. Fault Diagnosis: Precise Localization from Symptoms to Root Cause

4.1 Common Failure Modes

Trigger failure: Often due to abnormal gate drive circuit; can be diagnosed by checking the rise time of the trigger pulse using an oscilloscope (normal value ≤ 2μs)

Abnormal on-state voltage drop: Measured using a four-wire bridge; the normal value should be ≤ 1.8V (25℃)

Thermal breakdown: Local hotspots can be detected using an infrared thermal imager; a temperature difference exceeding 15℃ requires a warning

4.2 Diagnostic Tools and Methods

Dynamic tester: Can simulate power grid fluctuations and detect the conduction characteristics of the component under ±15% voltage deviation

Gate charge analyzer: Accurately measures the amount of charge required for triggering (normal range: 20-50μC)

Acoustic emission detection: Captures micro-discharge phenomena inside the thyristor using ultrasound

V. Industry Practices: User Feedback and Expert Recommendations

5.1 User Evaluation

“This component has reduced the energy consumption of our rolling mill system by 18%, with a payback period of only 2.3 years.” – Equipment Manager, a steel group

5.2 Expert Recommendations

Selection points: Select component capacity based on motor power, and it is recommended to reserve a 30% margin

Installation specifications: The spacing between components in the control cabinet should be ≥ 50mm to ensure unobstructed heat dissipation channels

Maintenance strategy: Conduct infrared temperature measurement quarterly and trigger characteristic testing annually

VI. Industry Trends: Technological Evolution for the Future

With the maturity of wide-bandgap semiconductor technologies such as silicon carbide (SiC), ABB is developing the third-generation bidirectional thyristor component. The upgraded version of 3BHL000986P3012, expected to be launched in 2026, will adopt a hybrid packaging technology of SiC and silicon, reducing switching losses by 60% and increasing the operating frequency to 5kHz.

VII. Conclusion: Driving Industrial Green Transformation

The ABB 3BHL000986P3012 bidirectional thyristor component, with its excellent performance, is becoming the preferred solution for energy-saving upgrades in medium-voltage drive systems. For enterprises pursuing the dual goals of carbon neutrality and intelligent manufacturing, investing in such technology is not only a choice to improve energy efficiency but also a strategic decision to build future competitiveness.