Application Scenarios

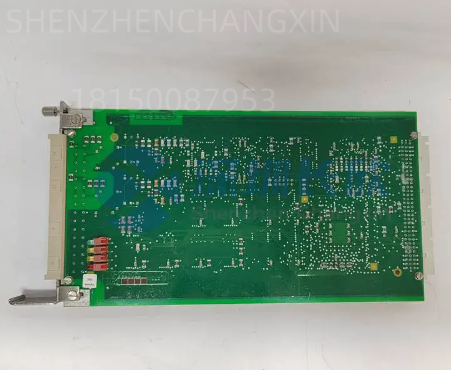

Inside the control cabinet of a 200MW combined-cycle power plant, the stable blue hue of the combustion monitor is the only acceptable sight. When ultraviolet (UV) flame scanners monitoring multiple burners send weak or noisy signals, the risk of a false “loss of flame” trip or, worse, a failure to detect an actual flame-out, becomes terrifyingly real. The ALSTOM 730475-D module is the guardian against this. Installed in the turbine’s Mark VI or similar control rack, it acts as the intelligent gateway for these signals. It conditions the raw, analog output from the UV scanners, filtering electrical noise and converting it into a robust, digital-ready signal for the main processor. Its primary value lies in providing a decisive, accurate “flame ON / flame OFF” status, which is the fundamental permit for fuel flow. It directly addresses the pain point of unreliable flame detection—preventing costly false trips that shutdown generation, while ensuring the turbine shuts down safely if a genuine flame failure occurs, protecting millions of dollars in hardware.

Parameter

Technical Principles and Innovative Values

Innovation Point 1: Intelligent Signal Conditioning for Critical Safety Loops: The ALSTOM 730475-D is not a simple pass-through card. It incorporates advanced signal conditioning circuitry designed specifically for the challenging environment of flame detection. This includes adjustable gain, configurable filtering to eliminate spurious pulses from coal dust or soot, and precise threshold detection. This intelligence ensures that the final “flame present” signal sent to the turbine’s Triple Modular Redundant (TMR) safety system is exceptionally reliable, minimizing nuisance trips.

Innovation Point 2: Seamless, High-Integrity Integration with Speedtronic Architecture: Its core innovation is its native, firmware-level integration into the ALSTOM Speedtronic control ecosystem. The module communicates seamlessly with the turbine’s main processor (like a board) over the system’s high-speed backplane. This deep integration provides deterministic data exchange and allows the module’s health and status to be monitored directly within the turbine’s Toolbox or HMI software, offering a level of diagnostic visibility and system cohesion that generic signal conditioners cannot match.

Innovation Point 3: Enhanced Diagnostics and Predictive Maintenance Cues: Beyond basic functionality, the ALSTOM 730475-D module often provides diagnostic data on the connected sensor loop. It can help identify deteriorating flame scanner performance, increasing signal noise, or trends towards threshold limits before they cause an operational issue. This transforms the module from a simple component into a predictive maintenance tool, enabling planning for scanner cleaning or replacement during scheduled outages, not forced outages.

Application Cases and Industry Value

A midwestern utility operating a fleet of ALSTOM GT11N1 gas turbines was plagued by intermittent, unexplained turbine trips that all traced back to the flame detection system. Investigations pointed to electromagnetic interference (EMI) from large motor starts affecting the long cable runs to the UV scanners. Replacing the standard interface cards with properly configured ALSTOM 730475-D modules was the solution. The modules’ superior filtering and shielding characteristics cleaned up the signal. After installation, the spurious trips ceased entirely. The plant manager reported, “The 730475-D cards gave us the signal integrity we needed. We went from several trips a year to zero related to flame detection, significantly improving our unit reliability factor and saving over $250.000 annually in lost starts and replacement power costs.”

Related Product Combination Solutions

ALSTOM TUR1 Control Module: The main turbine control processor; the 730475-D feeds it critical flame status data for the protection algorithms.

ALSTOM UVS1x Flame Scanners: The primary field device (e.g., UVS11. UVS12); its signal is conditioned by the 730475-D module.

ALSTOM Power Supply Assembly: Provides clean, regulated power to the entire rack containing the 730475-D and other control modules.

ALSTOM VCCC Communication Card: Facilitates communication between the turbine control rack and the plant DCS; status from the 730475-D is communicated network-wide via such cards.

ALSTOM Servo Driver Card: While not directly connected, the 730475-D’s flame signal ultimately governs the fuel commands sent to actuators driven by cards like the SRV1.

ALSTOM Turbine Fuel Interface Card: A critical safety card; it receives the finalized “permit to fire” signal derived from the 730475-D’s processed inputs.

Installation, Maintenance, and Full-Cycle Support

Installation and Maintenance: Installing an ALSTOM 730475-D module requires strict adherence to safety and ESD (Electrostatic Discharge) procedures. The turbine must be offline and locked out. Before removal, the specific channel should be placed in a “maintenance bypass” or “forced” state in the control software to prevent a trip. The old module is carefully extracted from its backplane slot, and the new ALSTOM 730475-D is firmly seated. Upon power-up, its configuration (gain, thresholds) must be verified or downloaded from the control system’s database. Routine maintenance involves periodic visual inspection for board integrity and connection tightness, monitoring of signal health and diagnostic parameters in the control software, and verifying its function during planned turbine startup sequences.

We provide comprehensive support for the ALSTOM 730475-D. Our commitment extends beyond supplying the genuine module. We offer technical documentation for installation and configuration. Our experts can assist with troubleshooting signal issues related to the flame detection loop. We understand that this component is part of a critical safety system, and we ensure the modules we provide are sourced to meet the stringent specifications required for reliable turbine operation. Our goal is to be your partner in maintaining the highest levels of availability and safety for your rotating equipment.