Introduction: The Benchmark for Mission-Critical Reliability

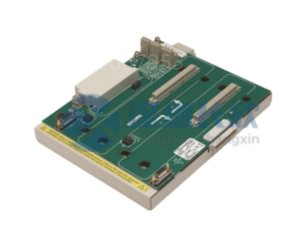

In the landscape of industrial control, where the cost of failure escalates from financial loss to environmental impact and public safety, equipment selection transcends mere functionality. The GE 8751-CA-NS stands as a paradigm of this philosophy, engineered explicitly for mission-critical operations in sectors such as power generation (including nuclear), oil & gas transmission, and chemical processing. This module is more than a component; it is a certified assurance of performance under duress. Its designation signifies a design pedigree that rigorously adheres to international industrial standards for electromagnetic compatibility (EMC), seismic withstand, thermal cycling, and functional safety. Unlike commercial-off-the-shelf (COTS) components adapted for industrial use, the 8751-CA-NS is born from the ground up to meet the exacting specifications of global regulatory bodies and industry best practices, making it the preferred choice for system integrators and end-users who cannot afford compromise.

Technical Specifications: Decoding the “Built to Standard” Design

1. Robust Electrical Design and EMC Compliance

The module’s immunity to electrical noise is foundational. It is designed and tested to meet or exceed stringent standards like IEC 61000-6-2 (Industrial Immunity) and IEC 61000-6-4 (Industrial Emissions). This means it can operate reliably in environments saturated with electromagnetic interference from variable frequency drives, high-power switching, and radio transmissions, without corrupting data or generating disruptive emissions that affect other sensitive equipment. Key features include:

Galvanic Isolation: High-grade isolation between field-side connections, logic-side circuitry, and communication ports prevents ground loops and limits fault propagation.

Surge and Transient Protection: Integrated protection circuits guard against lightning-induced surges (IEC 61000-4-5) and fast transient bursts (IEC 61000-4-4), common in industrial plants and outdoor installations.

Wide Operating Voltage Range: Designed to maintain functionality despite typical plant voltage sags and swells, ensuring continuous operation during grid disturbances.

2. Mechanical and Environmental Ruggedness

Built to endure the physical demands of industrial settings, the 8751-CA-NS exemplifies mechanical integrity.

Extended Temperature Range: It operates flawlessly across a wide ambient temperature range (e.g., -40°C to +70°C), crucial for outdoor substations or unheated equipment rooms in harsh climates.

Seismic Certification: For nuclear power plants and facilities in seismically active zones, specific variants of such modules undergo rigorous seismic testing (e.g., to IEEE 344 or IBC standards) to demonstrate their ability to remain functional during and after a seismic event. This is a non-negotiable requirement for safety-related systems in the nuclear industry, as highlighted by the stringent qualification processes for all equipment within such facilities.

Vibration and Shock Resistance: Its construction withstands the constant vibration from rotating machinery and occasional mechanical shocks, ensuring long-term solder joint and connector integrity.

3. Certifications and Compliance for Regulated Industries

The module’s value is underpinned by formal certifications. In addition to generic industrial standards, it may carry certifications relevant to specific sectors:

Functional Safety: Potential alignment with IEC 61508 (functional safety of E/E/PE systems) principles, making it suitable for use in Safety Instrumented Systems (SIS) up to a defined Safety Integrity Level (SIL).

Sector-Specific Approvals: For use in hazardous locations (Class I, Div 2 per NEC/CEC), or compliance with nuclear quality assurance standards (e.g., 10 CFR 50 Appendix B, NQA-1). These are not mere checkboxes but the result of a controlled design, manufacturing, and documentation process.

Real-World Applications: Where Standards Meet Reality

1. Nuclear Power Plant: Safety System Monitoring

In a GE Hitachi advanced boiling water reactor (ABWR) facility, arrays of GE 8751-CA-NS modules are deployed within the plant’s diverse monitoring and control networks. They interface with sensors measuring reactor coolant pump vibration, bearing temperature, and auxiliary system pressures. Here, the module’s EMC immunity and seismic qualification are paramount. During a routine test involving the energization of a large backup diesel generator, which creates massive electromagnetic noise, the modules continued to provide stable, uncorrupted readings to the control room. The plant’s I&C (Instrumentation and Control) manager stated, “In a nuclear environment, every component’s pedigree matters. We specify modules like the 8751-CA-NS because their compliance documentation is exhaustive and their field performance history is impeccable. They are a known, reliable quantity in our safety calculus.”

2. Long-Distance Pipeline: Remote Terminal Unit (RTU) Core

Along a transcontinental natural gas pipeline, unmanned compressor stations and block valve sites rely on RTUs for autonomous control and data transmission. The GE 8751-CA-NS forms the core I/O interface within these RTUs. Exposed to desert heat, mountain cold, lightning strikes, and significant vibration from compressor turbines, the module’s environmental ruggedness ensures data integrity. A pipeline operator reported that since standardizing on these industrially-hardened modules, unscheduled maintenance visits to remote sites due to I/O card failures have dropped by over 60%, significantly reducing operational costs and improving pipeline availability.

3. Pharmaceutical Batch Processing: Ensuring Product Quality

In a sterile pharmaceutical facility, precise control of bioreactor temperature, pressure, and agitation is critical for product efficacy and regulatory compliance. The 8751-CA-NS modules are used in the control cabinets adjacent to the process area. Their low-emission design (EMC) prevents them from interfering with sensitive analytical instruments, while their high immunity ensures that control signals remain accurate despite the noise from large-scale HVAC systems and motorized valves. This guarantees batch-to-batch consistency and prevents costly batch losses due to control system anomalies.

Expert Insights: The Economic and Operational Rationale

1. The Total Cost of Ownership (TCO) Argument

“Choosing a component built to industrial standards is an exercise in risk mitigation and life-cycle cost optimization,” explains Dr. Sarah Jensen, an engineering consultant specializing in critical infrastructure. “The upfront cost of a GE 8751-CA-NS is higher than a standard module. However, when you factor in the cost of a single failure in a critical operation—be it a plant trip, a safety system impairment, or a product spoilage incident—the investment is justified. Its extended mean time between failures (MTBF) and predictable performance reduce unplanned downtime, emergency maintenance, and operational risk, delivering a superior TCO.”

2. Simplifying System Certification and Compliance

For system integrators building solutions for regulated industries, using pre-certified components is a strategic advantage. “When we design a control skid for a liquefied natural gas (LNG) train or a safety system for a chemical plant, regulatory approval is a major project phase,” says Michael Torres, a lead systems integrator. “Specifying modules like the 8751-CA-NS, which already carry relevant industrial certifications, dramatically simplifies our own system-level validation and documentation burden. It provides auditors and clients with immediate confidence in the hardware foundation.”

3. Future-Proofing Through Standards Adherence

Standards represent collective industry wisdom on reliability and interoperability. “Adherence to open, international standards is a form of future-proofing,” notes Maria Chen from ARC Advisory Group. “A module built to IEC standards ensures not just robustness today but also a degree of interoperability and support longevity. As systems evolve and are upgraded over decades, this standards-based design facilitates integration and replacement, protecting the owner’s long-term capital investment.”

Conclusion: The Standard as a Promise

The GE 8751-CA-NS module embodies a fundamental truth in industrial automation: for critical operations, reliability cannot be an afterthought or a hopeful outcome. It must be engineered, tested, and certified into the product from its inception. By being “built to industrial standards,” this module offers more than a set of features—it offers a verifiable promise. It promises to withstand the electrical chaos of a plant floor, the physical rigors of the environment, and the relentless passage of time in continuous operation. In a world where industrial processes underpin modern civilization, choosing such components is not merely a technical decision; it is a commitment to safety, sustainability, and operational excellence. The GE 8751-CA-NS stands as a testament to that commitment, providing the unwavering reliability that critical operations demand and deserve.