Application Scenarios

At a 1.200 MW combined-cycle power plant in the Gulf Coast, repeated nuisance trips during grid disturbances threatened reliability contracts. Root cause analysis traced the issue to marginal trip logic timing in legacy protection cards. After replacing them with GE DS3800XTFP1E1C modules, engineers leveraged the card’s precise 2-out-of-3 voting and <10 ms response time to distinguish real faults from transient noise. Over the next 18 months, forced outages dropped to zero—even during Category 4 hurricane grid swings. For the plant’s controls lead, the DS3800XTFP1E1C wasn’t just hardware; it was the difference between penalty fees and performance bonuses.

Technical Principles and Innovative Values

Innovation Point 1: Hardware-Based Trip Voting

Unlike software-dependent PLCs, the DS3800XTFP1E1C uses dedicated FPGA or ASIC logic to execute 2oo3 voting at the hardware level—eliminating OS latency or cyber vulnerabilities. This ensures deterministic, sub-10ms response even under CPU load.

Innovation Point 2: Direct Solenoid Drive Capability

The module can directly switch 125 V DC trip solenoids (up to 2 A) without external relays, reducing component count and failure points in the final trip path—a key requirement for API 670 compliance.

Innovation Point 3: Fail-Safe by Design

All critical circuits on the DS3800XTFP1E1C are energize-to-trip or de-energize-to-trip configurable, but default to de-energize-to-trip—meaning any power loss, cable break, or module fault automatically triggers a safe shutdown.

Innovation Point 4: Seamless Integration with Mark V Architecture

The DS3800XTFP1E1C communicates natively with Mark V’s triple-modular redundant (TMR) controllers via the backplane, sharing real-time status with the HMI while maintaining an independent, hardwired trip path for maximum safety integrity.

Application Cases and Industry Value

A petrochemical facility in Saudi Arabia retrofitted its aging Frame 7EA gas turbine with a modernized Mark V system featuring DS3800XTFP1E1C modules. During a bearing temperature runaway event caused by oil coking, the DS3800XTFP1E1C received inputs from three independent RTDs, voted 2oo3. and tripped the unit in 8 ms—preventing a $20M rotor replacement. Post-incident review confirmed zero missed diagnostics, validating the module’s role as a “last line of defense.”

Similarly, a European district heating plant uses DS3800XTFP1E1C units to protect steam turbines driving generators and pumps. Thanks to hot-swap support in redundant racks, technicians replaced a faulty module during operation—avoiding a winter-season outage that could have left 50.000 households without heat.

Related Product Combination Solutions

DS3800HIOA: Mark V I/O Analog Module – provides sensor inputs to trip logic

DS3800HSVA: Servo Valve Output Card – works with DS3800XTFP1E1C for fuel control during trip

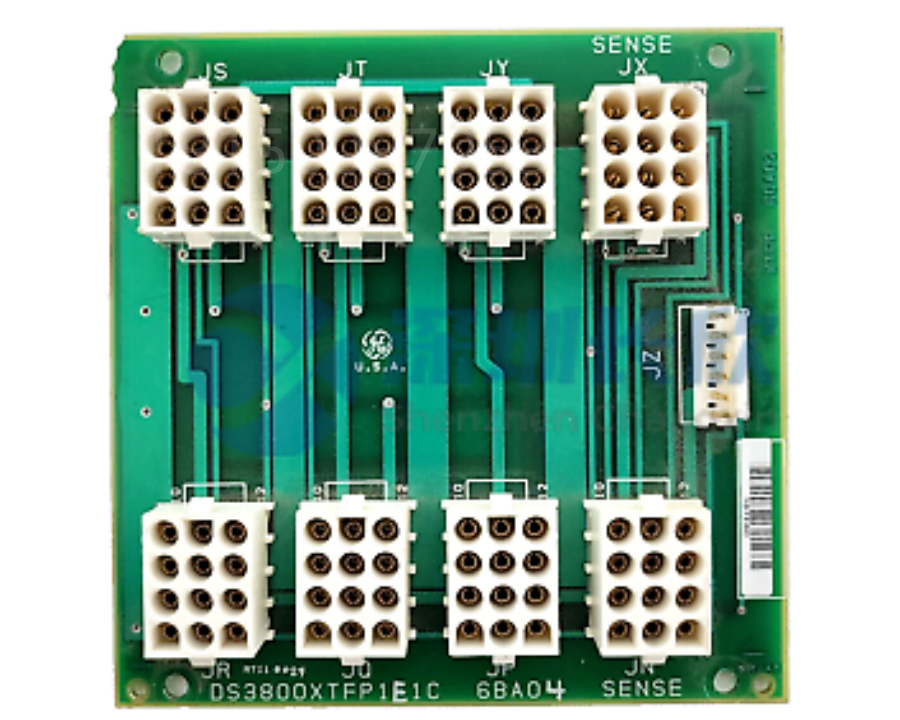

DS3800TCMA: Terminal Board for TFP Modules – interfaces field wiring to DS3800XTFP1E1C

Mark VIe IOTU: Input/Output Terminal Unit – allows DS3800XTFP1E1C integration in hybrid Mark VIe systems

DS3800PPOA: Power Supply Module – ensures stable voltage for critical trip processors

TBQC Chassis: Mark V Core Rack – houses DS3800XTFP1E1C and companion logic cards

ToolboxST Software: GE’s configuration suite – used to test and validate DS3800XTFP1E1C logic

DS3800XRPA: Relay Output Module – extends DS3800XTFP1E1C signals to plant-wide ESD systems

Installation, Maintenance, and Full-Cycle Support

Installing the GE DS3800XTFP1E1C requires alignment with the guide rails in a powered Mark V rack and firm insertion until the retention latch engages. All field connections route through a dedicated terminal board (e.g., DS3800TCMA) with clearly labeled trip, reset, and diagnostic points. Wiring must use shielded, twisted-pair cables with single-point grounding to prevent false trips from EMI.

Maintenance is simplified by front-panel LEDs indicating operational health and trip status. During routine tests, operators can simulate trip conditions via the ToolboxST software or hardwired test switches—verifying end-to-end functionality without turbine rotation. If replacement is needed, the module supports hot removal in redundant configurations, though full trip path validation is required post-installation.

We supply only genuine DS3800XTFP1E1C units—either new surplus from GE-authorized channels or professionally refurbished with full functional testing, including trip timing verification and LED diagnostics. Each unit includes traceable serial numbers and compatibility assurance for your specific Mark V or Mark VIe revision. Our engineering team offers commissioning support, SIL validation documentation, and migration guidance for plants transitioning to Mark VIe while retaining legacy trip integrity.