BENTLY 133396-01 in Power Generation: Turbine and Compressor Safety

Introduction

In the heart of modern power generation, gas turbines and compressors are indispensable components, driving efficiency and reliability in energy production. However, their operation demands rigorous safety monitoring to prevent mechanical failures, which can lead to costly downtime or even catastrophic events. The BENTLY 133396-01. a specialized input/output (I/O) module within the BENTLY Nevada 3500/53 series, plays a pivotal role in ensuring the safe and stable performance of these critical systems. Designed for digital量输入 applications, this module integrates seamlessly into turbine and compressor control frameworks, providing real-time data processing and anomaly detection capabilities that are essential for maintaining operational integrity in power plants. This article explores the technical features, industry applications, and safety benefits of the BENTLY 133396-01. highlighting its contribution to enhancing mechanical protection in power generation contexts.

Technical Overview of BENTLY 133396-01

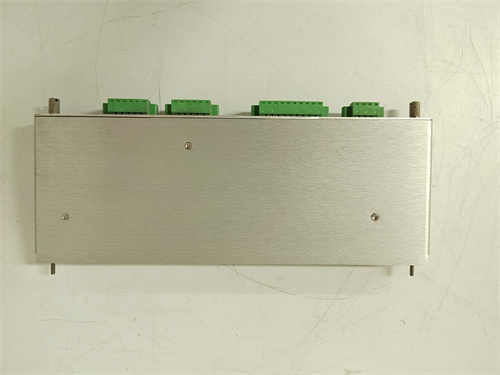

The BENTLY 133396-01 is a digital量输入模块 engineered for high-precision monitoring in industrial automation systems. It belongs to the 3500/53 series of BENTLY Nevada, which is renowned for its robust design and compatibility with diverse power generation equipment. This module features a compact form factor with integrated terminals, facilitating easy installation and maintenance in control panels. Its core functionality revolves around processing digital signals from sensors, such as proximity probes or magnetic pickups, and converting them into actionable data for control systems. Key technical attributes include:

Signal Processing: The module adeptly handles multiple digital input streams, enabling precise measurement of parameters like speed, position, and vibration. This capability is crucial for detecting subtle mechanical deviations before they escalate into major issues.

Real-time Monitoring: With low-latency communication protocols, the 133396-01 ensures instantaneous data transmission to supervisory systems, allowing operators to respond promptly to abnormal conditions.

Modular Design: As part of the 3500 framework, it supports带电插拔 (hot-swappable) functionality, minimizing disruption during maintenance or upgrades. This design enhances system redundancy and reliability, especially in mission-critical power generation environments.

Applications in Turbine and Compressor Safety

The BENTLY 133396-01 finds extensive use in gas turbine and compressor systems, where safety is paramount due to the high pressures and rotational speeds involved. Its applications span across monitoring, control, and protection layers:

Vibration and Position Sensing: In turbines, the module interfaces with vibration sensors to detect unbalanced rotor dynamics or bearing wear. For instance, in a combined-cycle power plant, the 133396-01 can monitor axial and radial vibrations, providing early warnings for potential blade fractures or misalignments. Similarly, in compressors, it helps track shaft displacement, preventing catastrophic failures like rotor-stator contact.

Speed and Phase Detection: The module’s ability to process digital signals from magnetic pickups enables accurate speed measurement. In a gas turbine, this functionality is vital for overspeed protection—wherein the module compares real-time speed data against preset thresholds and triggers alarms or shutdowns if anomalies are detected. This feature was instrumental in a recent incident where a turbine’s rotational speed exceeded safe limits, and the 133396-01’s timely intervention prevented mechanical damage.

System Integration: The module acts as a bridge between sensors and control systems, facilitating seamless data flow. In compressor stations, it integrates with temperature and pressure sensors to monitor thermal stress and flow rates, ensuring stable operation under varying load conditions.

Industry Case Studies and User Insights

Real-world applications of the BENTLY 133396-01 demonstrate its effectiveness in enhancing safety and reducing risks. Consider the following examples:

Case Study: Municipal Power Plant: A municipal waste-to-energy plant in Europe implemented the 133396-01 to monitor its gas turbines. The module’s vibration analysis capabilities identified a minor bearing defect during routine operation, prompting maintenance before the issue could compromise efficiency. Plant engineers noted that the module’s real-time alerts significantly reduced unplanned downtime, saving costs and boosting energy output.

User Testimonial: An operations manager at a natural gas compressor facility reported that the 133396-01’s digital量输入功能 improved system responsiveness. “During a peak load event, the module’s speed detection prevented an overspeed condition by triggering a controlled shutdown, averting potential equipment damage,” he stated. This experience underscores the module’s role in safeguarding high-value assets.

Expert Recommendations and Safety Benefits

Industry experts emphasize the BENTLY 133396-01’s contribution to mechanical protection in power generation. Its design aligns with best practices for turbine and compressor safety, offering:

Enhanced Reliability: By enabling continuous monitoring and rapid response, the module minimizes the likelihood of mechanical failures. Experts advise integrating it into redundant control systems to ensure fail-safe operation.

Operational Efficiency: The module’s data processing capabilities streamline maintenance workflows. For example, its ability to store and analyze historical vibration data helps predict wear patterns, supporting proactive maintenance strategies.

Global Compliance: The 133396-01 meets international safety standards, making it suitable for diverse power generation environments. Its use in projects like Finland’s Jyväskylä landfill gas power plant highlights its adaptability to extreme conditions.

Conclusion

The BENTLY 133396-01 stands as a cornerstone of safety in modern power generation, particularly for gas turbines and compressors. Its technical prowess in digital量输入 processing, coupled with real-time monitoring and modular design, ensures robust mechanical protection. From vibration detection to speed control, the module’s applications are indispensable in preventing failures and optimizing performance. As power plants increasingly rely on automation for efficiency, the 133396-01’s role in safeguarding critical infrastructure will continue to grow. By integrating this module into turbine and compressor systems, operators can achieve higher reliability, reduced risks, and enhanced operational sustainability.