Description

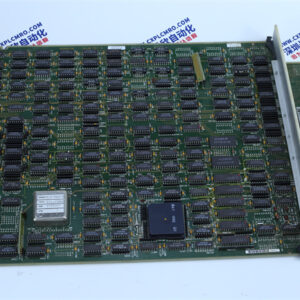

The VIBRO-METER 573-935-202C is a dual-channel vibration and position monitoring module from Meggitt Sensing Systems (now part of Spectris plc, marketed under the VIBRO-METER® brand). Designed for continuous machinery protection in accordance with API 670. this module processes signals from eddy-current proximity probes to monitor shaft displacement, bearing vibration, or casing motion. The VIBRO-METER 573-935-202C delivers real-time protection logic, analog outputs, and relay alarms—making it a critical component in turbine, compressor, and pump safety systems.

Engineered for high availability, each channel operates independently with full signal conditioning, gap voltage monitoring, and configurable alarm thresholds.

Application Scenarios

At a North Sea offshore gas platform, a critical centrifugal compressor began exhibiting erratic vibration readings due to aging analog monitors. After installing the VIBRO-METER 573-935-202C, engineers gained stable, noise-immune measurements from dual radial probes—even amid electromagnetic interference from VFDs and radio transmitters. The module’s independent relay outputs triggered a controlled shutdown when vibration exceeded API limits, preventing a catastrophic bearing failure that could have cost over $ 15M in downtime and repairs. In this harsh environment, the VIBRO-METER 573-935-202C proved to be more than a sensor interface—it was an insurance policy against operational disaster.

Parameter

表格

Note: The “C” suffix indicates conformal coating for enhanced environmental protection—ideal for marine, chemical, or humid environments.

Technical Principles and Innovative Values

Innovation Point 1: True Dual-Channel Independence

Each channel on the VIBRO-METER 573-935-202C has its own signal conditioner, alarm logic, and relay drivers—ensuring a fault in one channel never compromises the other, a requirement for critical API-compliant machinery.

Innovation Point 2: Integrated Gap Voltage Monitoring

Unlike basic monitors, the VIBRO-METER 573-935-202C continuously verifies probe health by measuring DC bias voltage. A drift outside ±10 V triggers a “Probe Fault” alert—preventing false negatives during slow rubs or mounting failures.

Innovation Point 3: Flexible Output Configuration

The 4–20 mA outputs can represent vibration (peak, RMS, or peak-to-peak), position (DC gap), or even temperature—enabling seamless integration with DCS or SCADA without external transducers.

Innovation Point 4: Field-Proven in Extreme Environments

With conformal coating (suffix “C”), wide temperature tolerance, and immunity to RFI/EMI, the VIBRO-METER 573-935-202C operates reliably on FPSOs, LNG trains, and geothermal plants where standard electronics fail.

Application Cases and Industry Value

In a U.S. petrochemical refinery, a steam turbine’s axial thrust position drifted undetected for weeks due to a failing legacy monitor. After retrofitting with the VIBRO-METER 573-935-202C, the system immediately flagged abnormal DC gap voltage during startup, revealing a cracked thrust bearing collar. The early warning avoided a $ 8M rotor replacement and 14-day unplanned outage. Maintenance supervisors now call it “the most trustworthy pair of eyes on our critical trains.”

Similarly, a hydroelectric plant in Scandinavia deployed the VIBRO-METER 573-935-202C to monitor generator shaft whip. Its low-noise design captured sub-micron vibrations, enabling predictive balancing and extending overhaul intervals by 3 years.

Related Product Combination Solutions

VIBRO-METER VM600 MEi Rack: Host chassis for 573-935-202C with power supply and communication backplane.

VIBRO-METER 573-935-101C: Single-channel version for less complex machines.

VIBRO-METER Proximity Probes (e.g., 9200-01-05-10-00): High-precision eddy-current sensors compatible with 573-935-202C.

VIBRO-METER 573-940-101C: Velocity input module for seismic/casing vibration monitoring.

VIBRO-METER VM900 System: Modern successor platform supporting Ethernet/IP and advanced diagnostics.

VIBRO-METER 573-990-101: Relay output expansion module for multi-level trip logic.

Bently Nevada 3500/42M: Functional alternative; 573-935-202C often used in hybrid or OEM panels as a drop-in replacement.

VIBRO-METER Configuration Software (VMConfig): Tool for setting alarm levels, scaling, and relay logic.

Installation, Maintenance, and Full-Cycle Support

Installing the VIBRO-METER 573-935-202C requires only a compatible rack (e.g., VM600 MEi), secure DIN-rail mounting, and connection of proximity probe cables to front-panel BNC or screw terminals. No calibration is needed—the module auto-scales based on probe sensitivity (typically 200 mV/mil). Front-panel LEDs indicate power, OK status, and alarm activation for quick visual checks.

Maintenance is minimal thanks to solid-state design and self-diagnostics. During routine rounds, technicians can verify probe health via the gap voltage test point. If replacement is needed, the module slides out without tools—minimizing turbine downtime.

We supply VIBRO-METER 573-935-202C units with original factory labeling, functional verification using calibrated proximity simulators, and a 12-month warranty. Every module undergoes 48-hour burn-in and API 670 compliance validation. Our team provides cross-reference support for Bently Nevada, GE, and SKF equivalents, along with obsolescence planning for legacy VM600 installations.

Contact us for a customized solution—whether you’re upgrading a protection system, replacing obsolete monitors, or securing spares for your critical turbomachinery. With the VIBRO-METER 573-935-202C, you’re not just measuring vibration—you’re safeguarding millions in assets and ensuring operational integrity where failure is not an option.