Application Scenarios

In a modern combined-cycle power plant, maintaining precise control over the gas and steam turbines is paramount for efficiency and safety. A failure in the control system can lead to millions in lost revenue from downtime. Here, the ABB 3BHE038369 P201 XZ C827 A module would typically function as a critical node within the plant’s DCS. It might be responsible for processing inputs from sensors monitoring turbine speed, temperature, and vibration, and then executing complex control algorithms to adjust fuel and steam valves with millisecond precision. Its robust design ensures continuous operation in the electrically noisy and thermally challenging environment of a power plant, directly addressing the core pain points of system reliability and control accuracy. This performance helps prevent unplanned outages and optimizes plant efficiency, showcasing the module’s value in mission-critical applications.

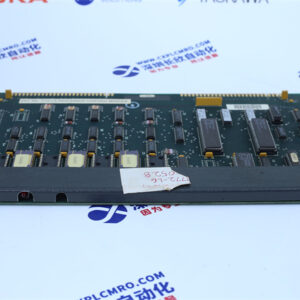

Parameter

Technical Principles and Innovative Values

The ABB 3BHE038369 P201 XZ C827 A embodies several key technical principles that contribute to its value in industrial automation.

Innovation Point 1: Modular and Scalable Architecture. The module is designed with a modular philosophy, allowing it to be seamlessly integrated into a rack or baseplate within a control system. This design simplifies system expansion and maintenance, as modules can be added or replaced without major reconfiguration, significantly reducing lifecycle costs and downtime.

Innovation Point 2: High Reliability in Harsh Conditions. Built to industrial-grade standards, the module utilizes high-quality components and design practices to ensure stable operation under conditions of temperature fluctuation, humidity, and electromagnetic interference. This ruggedness is critical for applications in power generation and heavy industry where equipment failure is not an option.

Innovation Point 3: Advanced Communication Capabilities. The module typically supports a range of industrial communication protocols (e.g., Profibus, Modbus), enabling it to act as a communication interface or a intelligent node within a networked control system. This allows for efficient data exchange between controllers, I/O units, and higher-level supervisory systems.

Application Cases and Industry Value

Case Study: Enhanced Control in a Hydroelectric Power Plant.

A hydroelectric dam facility was undergoing a control system modernization to improve the responsiveness and reliability of its turbine governors. The existing system lacked the processing speed and diagnostic capabilities for optimal performance. The new system design incorporated ABB’s AC 800PEC controllers, utilizing the 3BHE038369 P201 XZ C827 A (or a closely related module) as a key component for data acquisition and control logic execution for each turbine.

The result was a significant improvement in grid frequency stabilization and a reduction in mechanical stress on the turbines during load changes. The high-speed processing and reliability of the control modules allowed for finer control over the wicket gates, leading to more efficient power generation. Plant engineers reported a marked increase in system availability and a decrease in maintenance interventions, directly attributable to the stability provided by the new control hardware. This case underscores the module’s role in enhancing both the economic and operational performance of critical infrastructure.

Related Product Combination Solutions

A complete control solution often involves several interoperating components. Key products that synergize with the 3BHE038369 P201 XZ C827 A include:

AC 800PEC Controller Main Units (e.g., PM803F): The central processors that rely on modules like the 3BHE038369 P201 XZ C827 A for expanded functionality and I/O handling.

S800 I/O Modules (e.g., AI810. DI810): These peripheral modules provide the actual interface to field sensors and actuators, communicating with the central controller via the backplane where modules like the 3BHE038369 P201 XZ C827 A are installed.

Communication Interface Modules (e.g., CI854): Modules that enable the control system to connect to broader networks (e.g., industrial Ethernet, Profibus), working in concert with processing modules.

Power Supply Units (e.g., SD832): Provide stable and redundant power to the controller chassis and all installed modules, including the 3BHE038369 P201 XZ C827 A.

Tension Clamp Terminals (e.g., TU847): Used for connecting field wiring to the I/O modules, ensuring secure and reliable connections in the same system framework.

Installation, Maintenance, and Full-Cycle Support

Installation and Maintenance: The ABB 3BHE038369 P201 XZ C827 A is designed for straightforward installation into a compatible ABB control system rack. Proper procedure requires that the system is completely powered down and appropriate electrostatic discharge (ESD) precautions are taken. The module slides into a dedicated slot and is secured in place. Maintenance is primarily preventive, focusing on ensuring a clean, climate-controlled environment for the control cabinet and periodically checking system diagnostics via engineering software for any anomalies. Module replacement should be performed by qualified personnel.

Full-Cycle Support: Sourcing authentic ABB components is critical for system integrity and longevity. We provide genuine 3BHE038369 P201 XZ C827 A modules, ensuring compatibility and performance. Our technical support can assist with integration planning and troubleshooting. Furthermore, we stand behind our products with clear warranties and a commitment to helping you maintain operational uptime.