GFD212A

Siemens Industrial Control Series GFD212A Frequency Detection & Signal Conditioning Module

(The GFD212A module is part of Siemens’ portfolio for power system monitoring and industrial drive control, with “GFD” standing for “Grid Frequency Detection”—indicating its core function of measuring and processing AC frequency signals. It is widely integrated with Siemens’ Siprotec protection relays, Sinamics drives, and Simatic PLCs, serving as a key component for frequency-dependent control in scenarios like power grid synchronization, motor speed monitoring, and renewable energy (solar/wind) inverter control.)

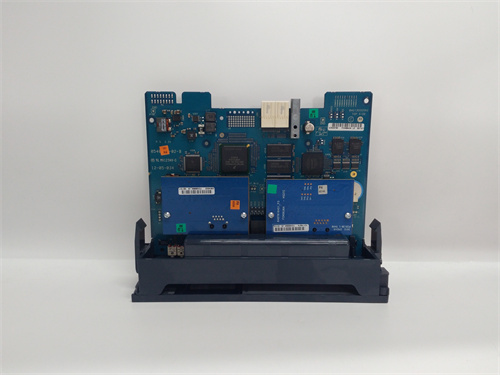

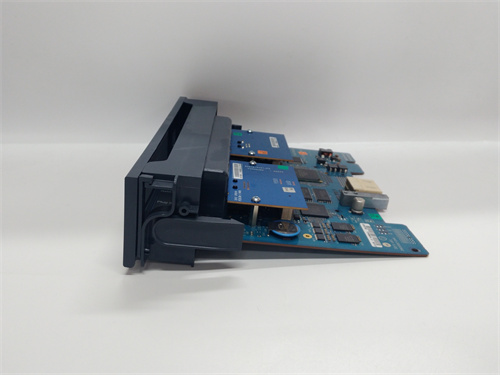

2. Product Description

The GFD212A module is a high-precision frequency detection device tailored for industrial and power system applications, such as fossil fuel power plant turbine-generator synchronization, wind farm grid connection, and large motor speed regulation. In a coal-fired power plant’s generator synchronization process, for example, this module continuously monitors the generator’s output frequency (typically 50Hz/60Hz) and the utility grid frequency. It receives 3-phase AC voltage signals (100V AC or 220V AC) from the generator’s voltage transformer (VT) and grid VT, conditions these signals via built-in filtering and amplification circuits, and converts them into digital frequency data with ±0.001Hz accuracy.

This precise frequency data is then transmitted to the Siemens Siprotec 7UT68 protection relay, which uses it to adjust the turbine’s speed governor—ensuring the generator’s frequency matches the grid frequency within a ±0.1Hz range before synchronization. This prevents “off-frequency” connection, which could cause voltage surges, equipment damage, or even grid instability. The GFD212A also features frequency deviation alarms: if the generator frequency drifts beyond a user-defined threshold (e.g., 49.5Hz-50.5Hz), it triggers a relay output to alert operators and initiate corrective actions (e.g., adjusting fuel supply to the turbine).

Another key application is wind farm inverter control: the GFD212A monitors the grid frequency in real-time and sends frequency signals to the wind turbine’s inverter. If the grid frequency drops below a critical level (e.g., 47Hz for low-frequency ride-through), the module signals the inverter to reduce power output or disconnect temporarily—complying with grid codes (e.g., IEC 61400-21) and protecting the grid from overload. The module’s robust design includes surge protection (IEC 61000-4-5, 10kV) and wide temperature tolerance, making it suitable for harsh outdoor environments (e.g., wind turbine nacelles or power substation control rooms). It also supports remote configuration via Siemens’ PACTware software, allowing engineers to set frequency ranges, alarm thresholds, and signal output types without on-site visits.

3. Product Parameters

3.1 Frequency Detection Parameters

- Input Signal Type: 3-phase or single-phase AC voltage (configurable via DIP switches)

- Input Voltage Range: 85V AC – 265V AC (50Hz/60Hz); 100V AC ±10% (rated for power system applications)

- Frequency Measurement Range: 40Hz – 70Hz (standard); 10Hz – 100Hz (extended range, configurable)

- Measurement Accuracy: ±0.001Hz (at rated voltage, 25°C); ±0.01Hz (full temperature range, -25°C-70°C)

- Resolution: 0.0001Hz

- Response Time: ≤10ms (for frequency changes ≥0.1Hz); ≤50ms (for frequency changes ≥0.01Hz)

- Input Impedance: ≥1MΩ (AC, 50Hz/60Hz)