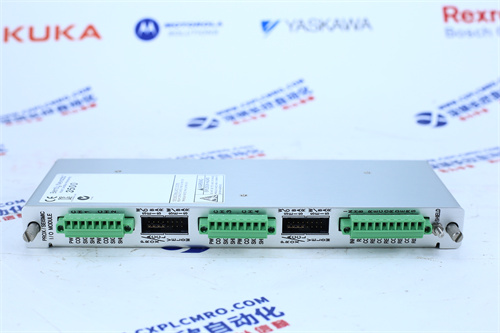

ABB PCD232A 3BHE022293R0101

ABB PCD232A 3BHE022293R0101 Process Control and Data Acquisition Module (acts as a “versatile data hub” in industrial automation systems, specializing in real-time collection, processing, and transmission of process data. With multi-channel input/output capabilities and robust communication functions, it enables seamless integration into distributed control systems for industries like power generation, chemical processing, and manufacturing)

Product Description

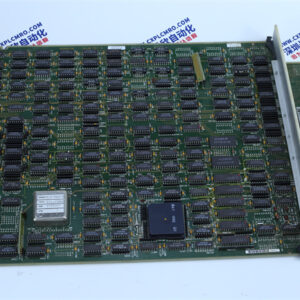

The ABB PCD232A 3BHE022293R0101 is a compact yet powerful process control module designed for medium-scale industrial applications, such as boiler control systems in power plants and batch processing lines in chemical factories. In a coal-fired power plant’s boiler control loop, this module connects to temperature sensors (RTDs and thermocouples) across the boiler tubes, flue gas analyzers, and pressure transmitters. It samples data at a rate of 100Hz per channel, converting analog signals into digital values with high precision, then executes pre-programmed control logic to adjust fuel flow and air supply. This ensures boiler efficiency remains above 92% while keeping emissions within regulatory limits (e.g., NOₓ < 50mg/Nm³).

In pharmaceutical batch production, the module manages recipe-based operations by coordinating with valves, pumps, and mixers. It records critical process parameters (temperature, pH, mixing speed) with time-stamping accuracy of ±1ms, supporting compliance with FDA 21 CFR Part 11 requirements for data integrity. The module features a modular firmware architecture that allows custom control algorithms to be uploaded via its configuration port, enabling adaptation to unique production processes without hardware modifications. Its built-in data buffering (up to 10,000 records) ensures no data loss during temporary communication interruptions, with automatic synchronization once connectivity is restored.