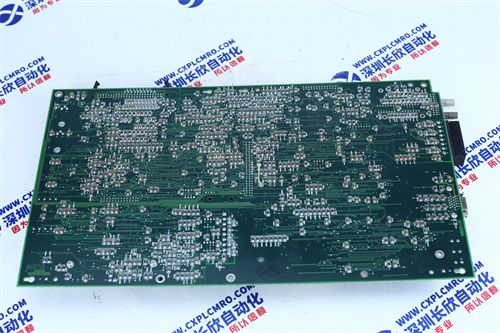

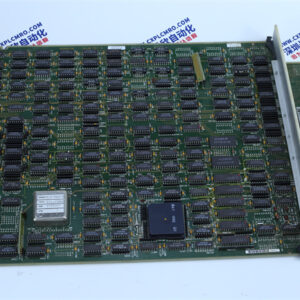

IS200EPMCH1

General Electric (GE) IS200EPMCH1 Power Module (Mark VIe Turbine Control System Power Supply Unit)

Product Description

The IS200EPMCH1 is a critical power supply module designed for GE’s Mark VIe turbine control system, responsible for delivering stable and regulated power to key control components such as processors, I/O modules, and communication interfaces. Its primary function is to convert incoming AC voltage (typically 110V or 220V AC) into multiple isolated DC outputs, ensuring reliable operation of the turbine control system in power generation, oil & gas, and industrial turbine applications—for example, maintaining consistent power to the speed control loop of a gas turbine, where voltage fluctuations could lead to speed instability (±0.1% of rated speed) and potential safety risks.

Featuring a redundant design (with dual internal power paths), the module provides fail-safe operation: if one power path fails, the other automatically takes over within 10ms, preventing control system downtime. This redundancy is critical for turbines operating in combined-cycle power plants, where an unplanned shutdown can cost $50,000+ per hour. The module delivers four isolated DC output channels: two 5V DC (3A each) for logic circuits, one 15V DC (1A) for analog circuits, and one 24V DC (2A) for relay coils and sensors, eliminating cross-talk between sensitive electronics (e.g., 5V microprocessors) and higher-power devices (e.g., 24V solenoid valves).

Efficiency is a key feature: the module achieves 85% efficiency at full load (110V AC input), reducing heat generation in control cabinets (e.g., a 24-hour operation produces 150kcal less heat than a 75% efficient supply, lowering cooling system load). It incorporates active power factor correction (PFC), ensuring a power factor of ≥0.95 at 50/60Hz, which minimizes harmonic distortion on the input AC line—critical for compliance with IEEE 519 standards in utility-connected power plants.